Laser Soldering

Laser soldering enables soldering processes

that have been abandoned for automation

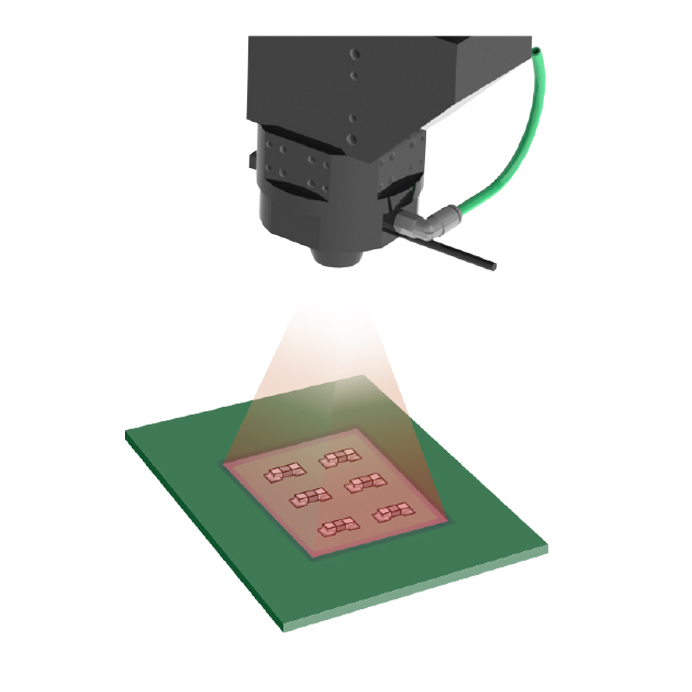

As electronic circuit boards become thinner and electrical components more multilayered, technology is evolving so rapidly that conventional methods are no longer applicable. Laser soldering makes it possible to solder ultra-fine areas that are difficult to reach with conventional soldering irons.

We have extensive experience with both solder paste and wire solder.

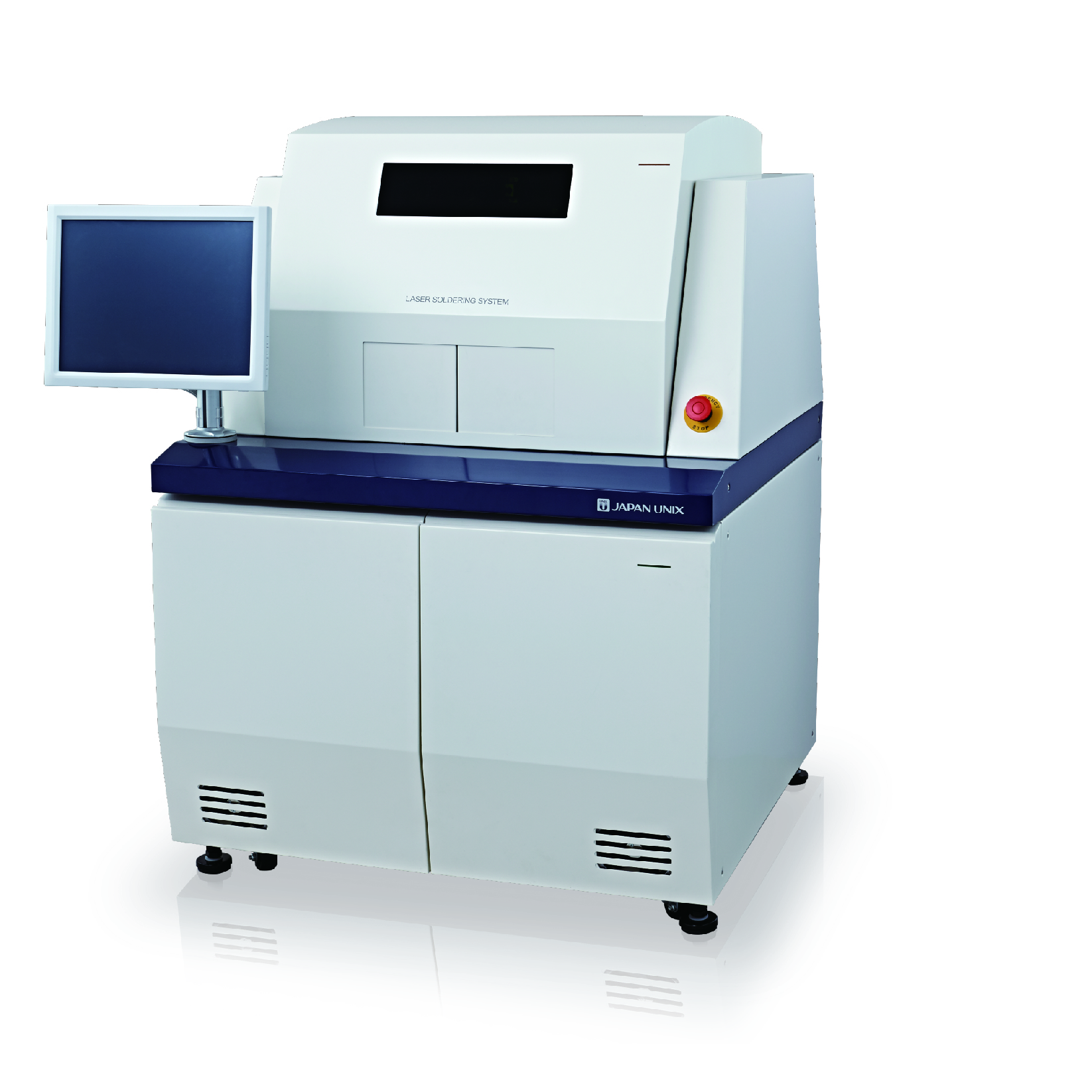

JAPAN UNIX Laser Systems

Further development and higher quality!

Innovation in soldering and process management made possible by laser soldering. Not only “soldering”, but also “laser soldering unit”, “temperature control function” and “soldering management software” have been combined to create Japan Unix’s unique laser soldering system.

What is the difference between a “surface heat generation” and ” thermal conduction”?

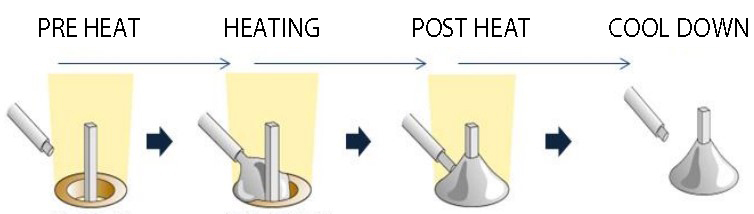

In soldering, tip soldering is basically a 3 step process that encompasses pre-heating of soldering points, applying heat to supply the solder, and then post-heating to shape the solder and finish it. This workflow is the same whether using iron tip soldering or laser soldering, but the method of applying heat to supply the solder differs, and this is very important to understand.

Feature

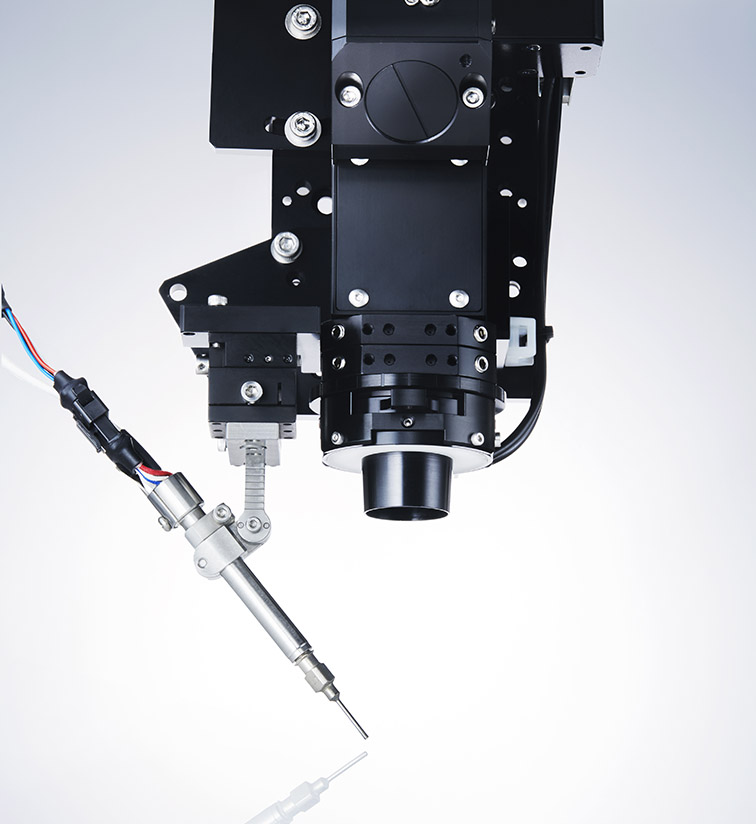

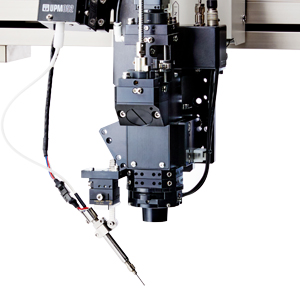

ULD-02 Laser Soldering Unit for a New Era of Connected, Visualized Soldering

Now that laser soldering has been established as one of the post-processing methods, the new laser soldering unit has been developed to achieve a higher level of process control than simple soldering. In particular, traceability and temperature measurement and control functions have been improved.

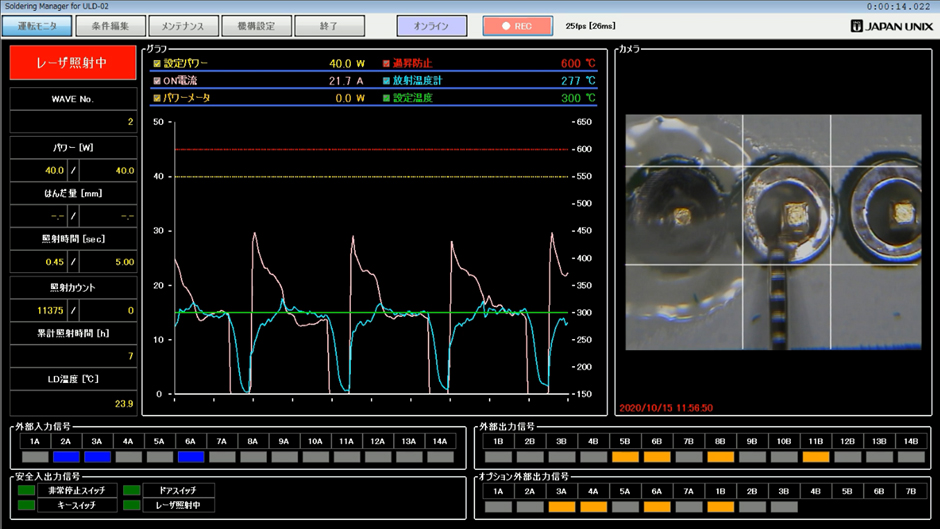

Advanced Process Control with Thermo Pro™ and Soldering Manager

In addition to conventional laser soldering control elements (power, time, etc.), the Thermo Pro™ temperature control function enables temperature management and control during soldering. In addition, when used in conjunction with the Soldering Manager Pro soldering management software, it is possible to monitor each soldering condition in real time and store the data on a PC. A video storage function using a coaxial camera can also be installed, allowing improved production control even from a distance.

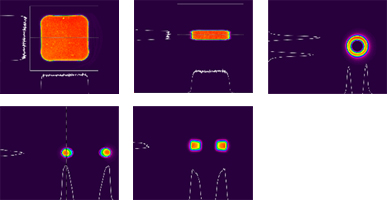

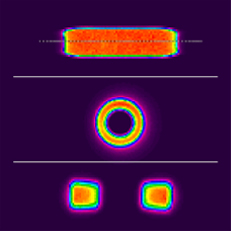

Optimized laser shape improves soldering efficiency!

Supports both SMT and rework

Optimized laser shape for highly efficient heat delivery. Supports not only perfect circles, but also ellipses, squares, rings, and other irregular shapes. Multi-φ function changes the laser spot size without changing the Z-axis (working distance). Optimization of laser geometry is possible even with different pad sizes. Area Laser is not limited to conventional post-process soldering, but also supports SMT as a local reflow process, and is compatible with Thermo Pro™ and Soldering Manager Pro, allowing visualization of the reflow process.

Equipped with external editing function

Data link communication allows external editing of conditions. Enables consistent interface design and easy condition editing even in highly integrated facilities.

Solder feed control is also available

The ULD-02 controller also controls the resin solder. One controller can control laser and solder together for easier operation.

Options and Solutions

Thermo Pro™

Temperature Control Function

Atypical Spot Laser

Adjustable spot shape and diameter.

Area Laser

Simultaneous Multi-Point Soldering

Soldering Manager

Soldering Management Software

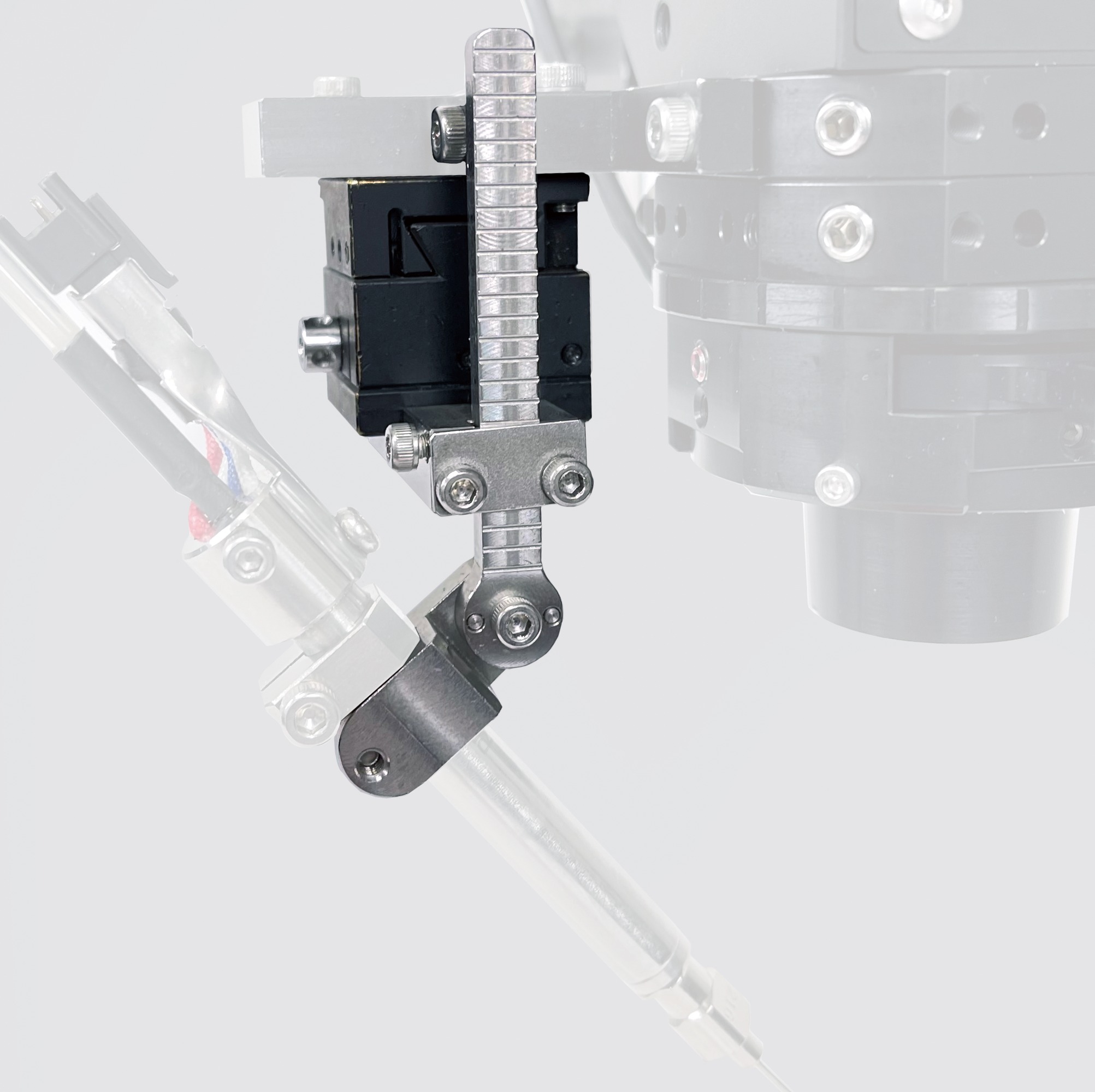

Lock-on Mechanism

for Laser

Multi-diameter Laser

Variable spot diameter

Flash Soldering

Double Speed” Laser Soldering

Robots

UNIX-DF Series

Desktop Type

UNIX-FR Series

Horizontal multiple-Joint

UNIX-GF Series

Gantry Type

Standard Configuration

Laser Controller

ULD-02E

Laser Driver

ULD-02D

Laser Oscillator

ULD-02G

Touch Panel Control Box

ULD-TPU

Laser Head

Soldering Manager

Free version for ULD-02

Reference Videos

Robotic Laser Solodering

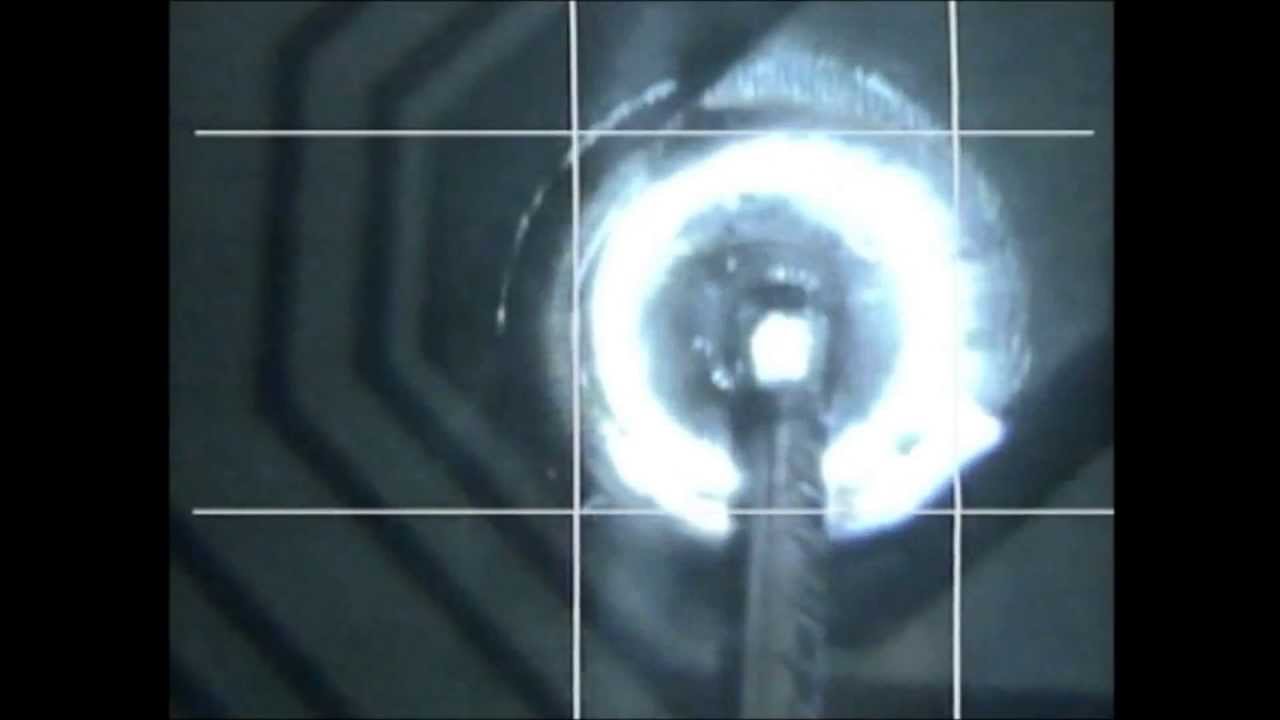

Laser soldering irradiation scene

Assembly video of laser soldering of micro components. High speed and high precision soldering operation can be seen.

High power laser soldering

High Power Laser vs. Normal Laser Comparison Video

Laser soldering is now used not only for micro components and high-precision parts, but also for parts that require high heat capacity, such as automotive components.

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español