Integration system

Full / Semi Customized Soldering System

Customization for soldering system is available with our original products to suit customers infrastructural needs. Choose either full or semi custom-made. By working off of clients’ internal specifications, we can provide customers the best answer on the entire soldering automation process. Nowadays, seamless and wasteless production environments are highly demaned at any factories. Our soldering system perfectly integrate with pre & post soldering operation and our experienced experts support from intelligent automation designs to the integration of soldering automation systems for your production lines.

Semi-customization

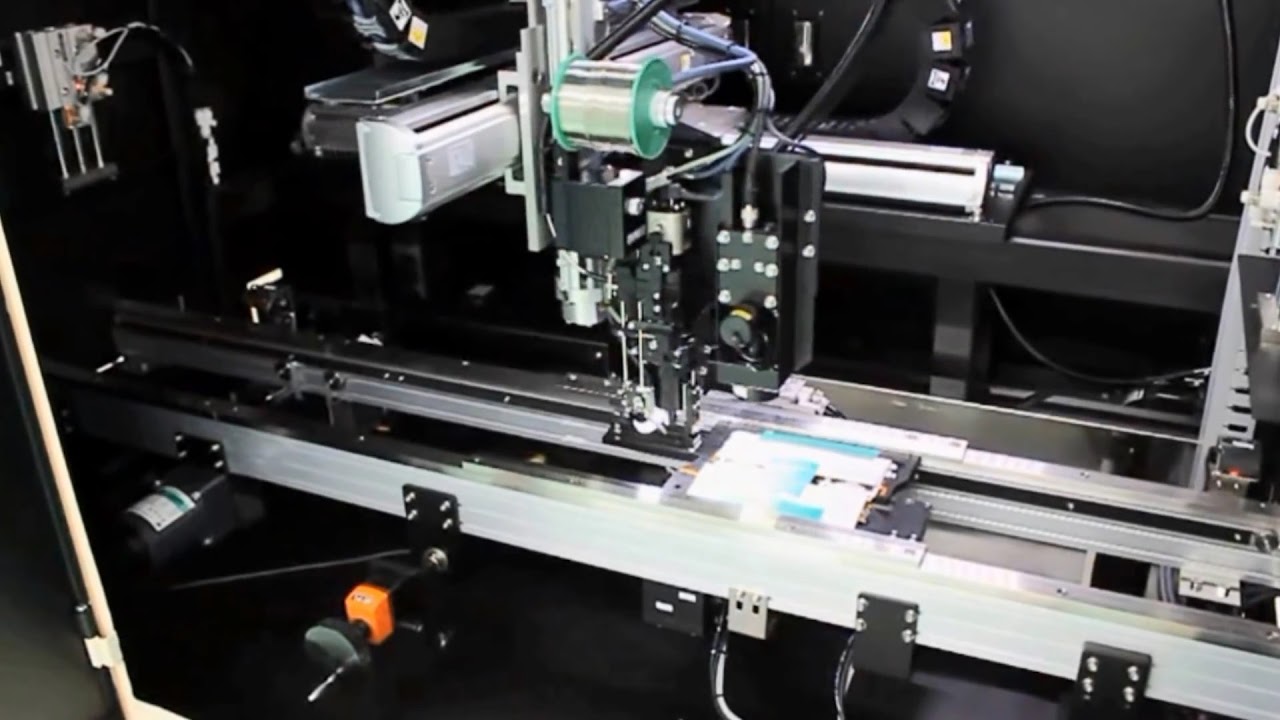

Existing soldering systems that have been developed to solve various customers automation issues.

Choose one from our existing models, which are semi-automated types, fully automated conveyance systems, and more to fit your requirements. The system includes an inline soldering robot or a desktop soldering robot. Contact soldering, laser soldering or ultrasonic soldering is adoptable

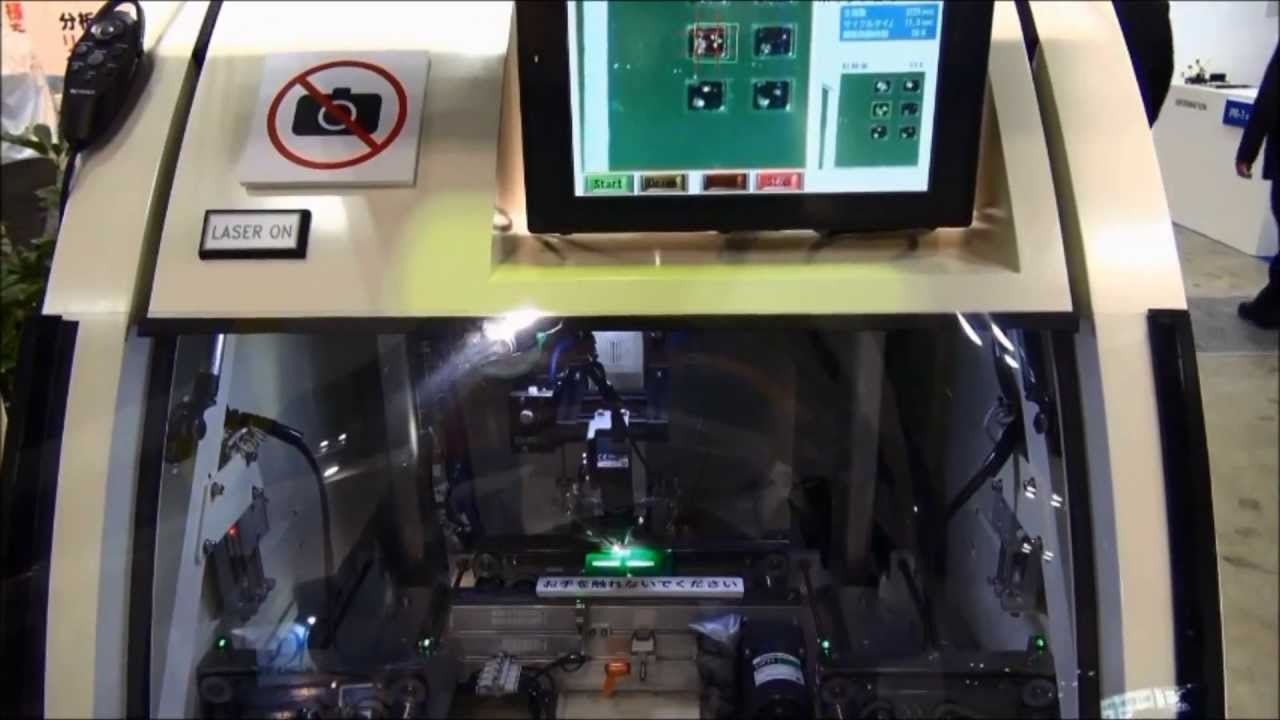

Smart laser soldering system with conveyer

UNIX-LS1

UNIX-LSX

Full Customization

Providing you with a full suite of advice on sizing and dimensions, electrical and mechanical device design, safety covers with sensors, loaders and unloaders, automated conveyance, and more.

Reference Videos

Integrated soldering system

Laser soldering system with conveyor

This system is widely used for lines working with micro components such as smartphones and others.

Integrated soldering system

Compact laser soldering system

Our newest laser soldering system with conveyor. Using a patented laser pin-point shoot function with ccd camera.

Three Methods to Choose From

Safe and reliable construction methods backed by tradition

Soldering with an iron tip has the longest history and is the most established technology in terms of reliability. However, modern technology requires a deeper understanding of soldering theory and new techniques to handle difficult applications

The latest soldering method that is attracting attention from around the world.

While laser soldering is gaining popularity as a new method, it cannot be used as a direct substitute for iron soldering, as the heating process varies. To fully benefit from laser soldering, it is vital to understand its characteristics and the appropriate handling techniques, otherwise its advantages may be lost. This article outlines the fundamental principles of laser soldering and the necessary precautions for its optimal use.

Ultrasonic turns conventional wisdom upside down. Soldering even on glass or ceramics

Conventional soldering basically involves bonding solder (tin) with a metallic substrate. Ultrasonic is an advanced technique that enables solder to bond with glass or non-metallic materials.

As renewable energy sources are attaining widespread use around the world.

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español