Multiple-joint Soldering Robot

Product Lineup

Equipped with servo motors. The pinnacle of soldering robots.

The SOLDER MEISTER FR series, the highest-end model developed for automated soldering.

High reliability quality, IoT, safety, workability, line tact, and all automation line issues are solved. Various applications can be added to realize automation of difficult soldering.

UNIX-FR Series (Vertical)

Vertical multiple-Joint soldering robot. Soldering can be performed from an optimal angle even on the surface of 3D Shape.

UNIX-FR Series (Scara)

Horizontal multiple-Joint soldering robot. Supports not only soldering by iron but also laser soldering.

Compatible with Various Production Lines

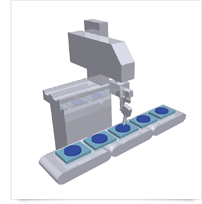

In-line

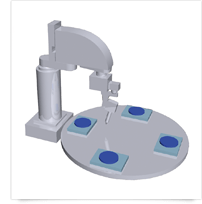

Indexing Rotary Table

2 sliders

Three Methods to Choose From

Safe and reliable construction methods backed by tradition

Soldering with an iron tip has the longest history and is the most established technology in terms of reliability. However, modern technology requires a deeper understanding of soldering theory and new techniques to handle difficult applications

The latest soldering method that is attracting attention from around the world.

While laser soldering is gaining popularity as a new method, it cannot be used as a direct substitute for iron soldering, as the heating process varies. To fully benefit from laser soldering, it is vital to understand its characteristics and the appropriate handling techniques, otherwise its advantages may be lost. This article outlines the fundamental principles of laser soldering and the necessary precautions for its optimal use.

Ultrasonic turns conventional wisdom upside down. Soldering even on glass or ceramics

Conventional soldering basically involves bonding solder (tin) with a metallic substrate. Ultrasonic is an advanced technique that enables solder to bond with glass or non-metallic materials.

As renewable energy sources are attaining widespread use around the world.

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español