Products

Product Category List

Automatic Soldering Robot

Versatile desktop type. Once programmed, it can consistently perform with the same quality as skilled workers by simply pressing the start button.

Laser Soldering

Laser soldering enables soldering of electronic boards that are becoming much finer, and electric/electronic components that are becoming multi-layered, which are difficult to perform soldering with conventional soldering irons.

Soldering Management Software

Real-time display of robot operation status. Recording images and data enables higher process control at the work site.

Soldering Peripheral Products

Soldering process challenges are diverse. We offer a rich set of expandable options based on customer feedback.

New Product Information

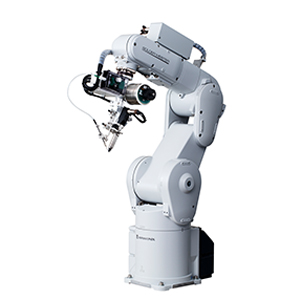

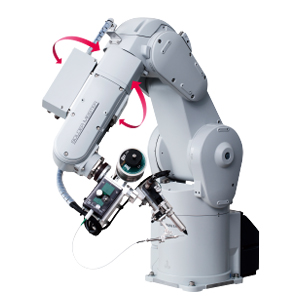

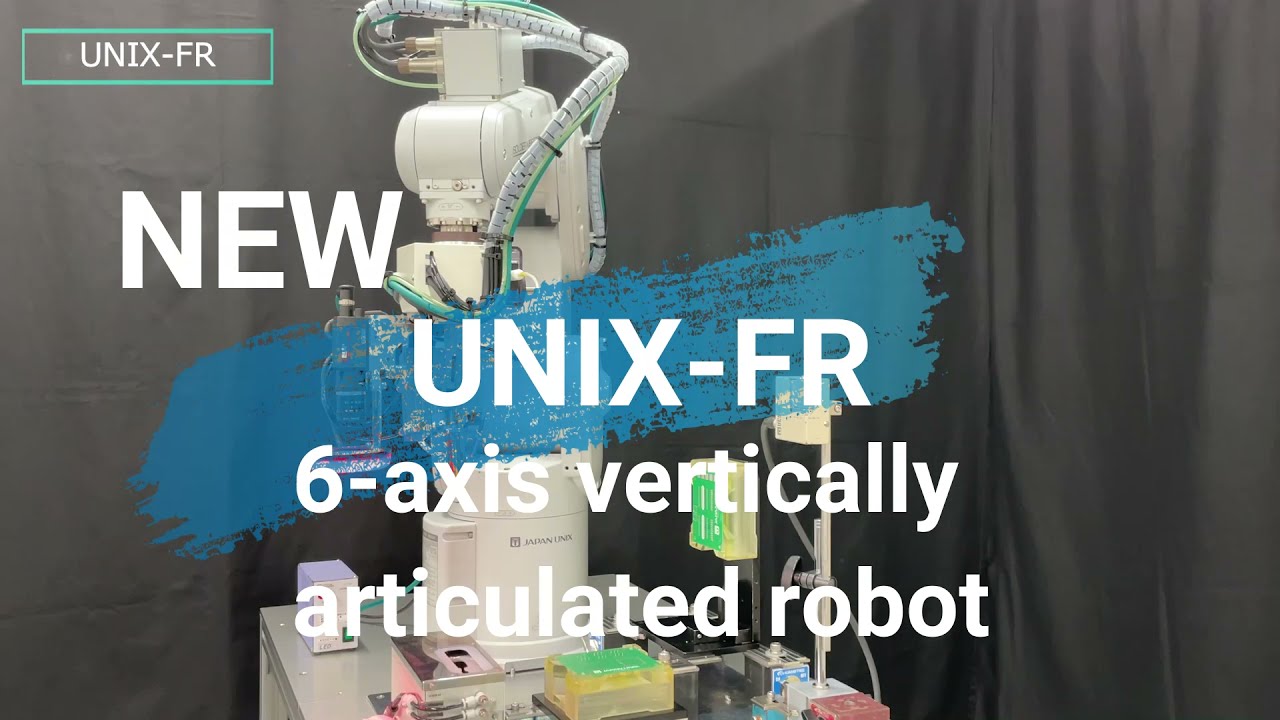

Advanced Vertical Multiple-joint Robot

UNIX-FR

A New Generation of Multiple-joint Type Robot for the Era of Full Automation

Enhanced communication network function for output and storage of soldering-related data, and comprehensive software that can be used regardless of operator skill.

- Optimum soldering angle is achieved even on angled mounting surfaces.

- Space-saving installation.

- Real-time monitoring and record keeping for soldering information is possible.

- Communication control for soldering conditions and settings from outside is possible.

- Soldering conditions can be easily edited programmatically with "Soldering Configurator," a dedicated PC software.

- Dedicated soldering commands are used to make robot teaching easier to understand.

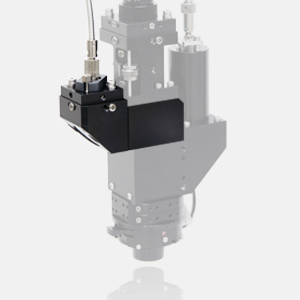

Laser soldering temperature management and control functions

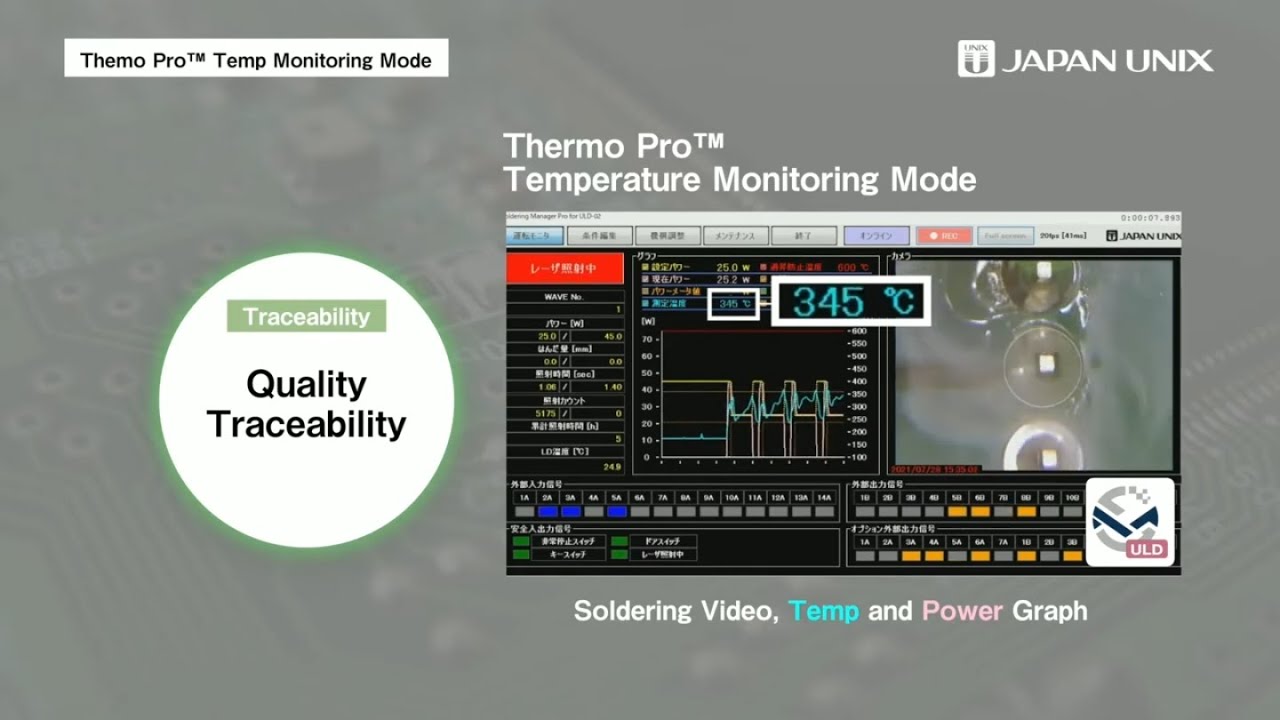

Thermo Pro™

Making Laser Soldering "Visible"

What is Thermo Pro™?

Thermo Pro™ is the generic name for laser soldering systems controlled by a pyrometer. In addition to conventional control items (output, time, etc.) in laser soldering, Thermo Pro™ enables temperature management and control during soldering.

- When used in conjunction with Soldering Manager, the measured temperature is displayed as a graph.

- A temperature band determination function that can output when the temperature is out of the set temperature band.

- Optimization of conditions based on laser output when temperature is controlled.

- Utilized not only for process control during mass production, but also for optimization during evaluation.

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español