Steve’s Tech Article “Webinar : What is Area Laser Soldering?”

Steve’s Tech Article “Webinar : What is Area Laser Soldering?”

Table of Contents

- Introduction

- Features of Area Laser

- Applications of Area Laser

- Benefits and Advantages of Area Laser

- Temperature Control and Quality Management

- Conclusion

- Related Products and Services

The webinar held in the past has been re-edited and re-presented by our virtual employee: Steve Honda on Article!

Watch the video of this Article here

Introduction

Today, I would like to introduce our new area laser technology products. I will explain the specific features of the area laser and its applications in detail.

We started selling laser soldering technology about 20 years ago and have accumulated a lot of achievements over the years. Based on the knowledge gained during the evolution of this technology, the new area laser technology was developed.

Features of Area Laser

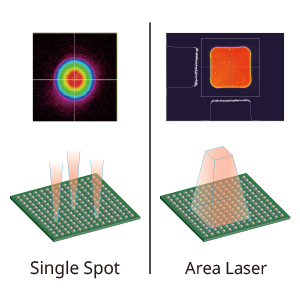

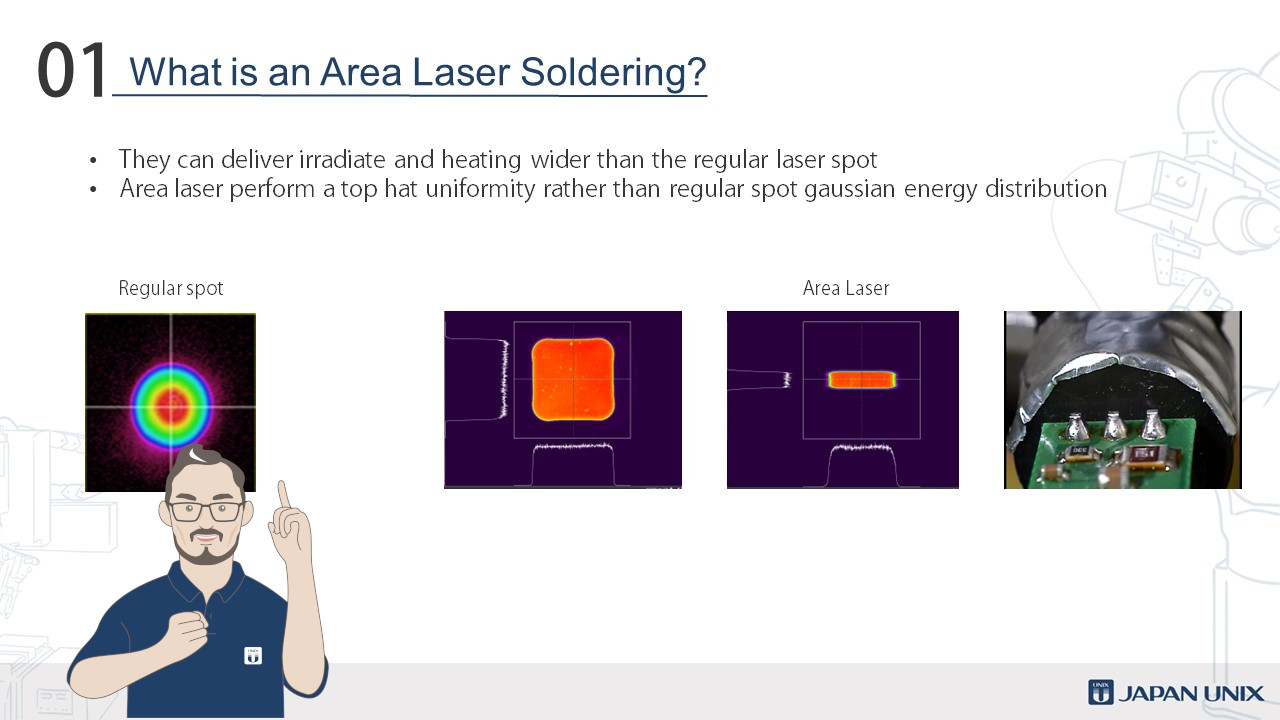

Traditional lasers used a single spot method, soldering one point at a time. On the other hand, the area laser irradiates a wide area uniformly, characterized by its uniform energy distribution. This uniform energy distribution allows heating up to the temperature where the solder melts without melting the resin.

Specifically, in a typical single-spot laser, the melted solder reflects and melts the resin on the sides. However, with an area laser, such issues do not occur. By watching the actual video, you can see that the solder melts with the irradiation of the area laser while the resin on the sides does not melt at all. The dispersed energy density prevents burning due to laser light reflection.

Applications of Area Laser

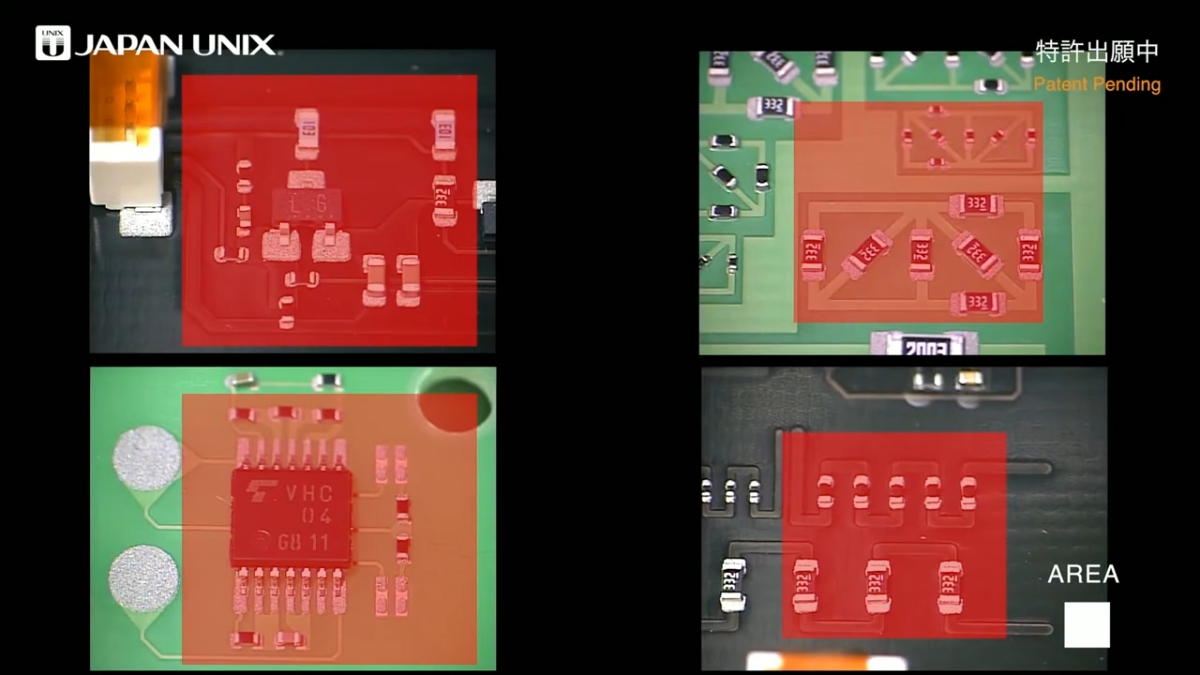

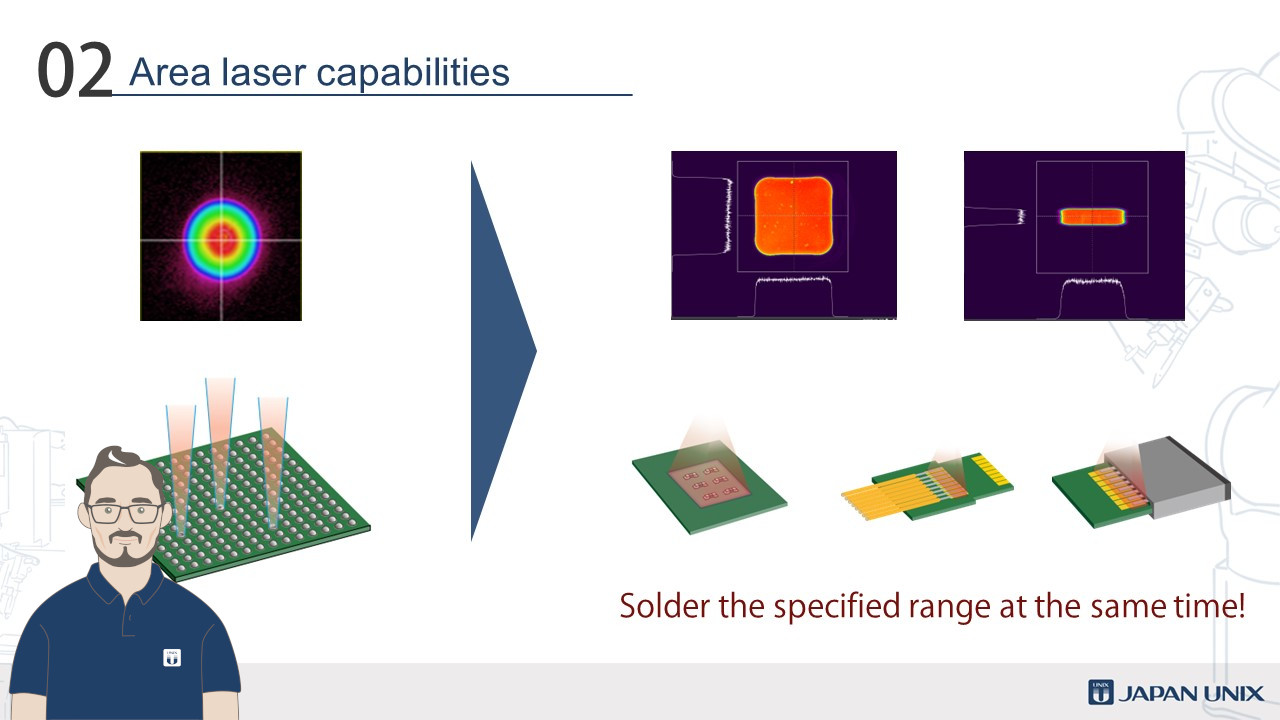

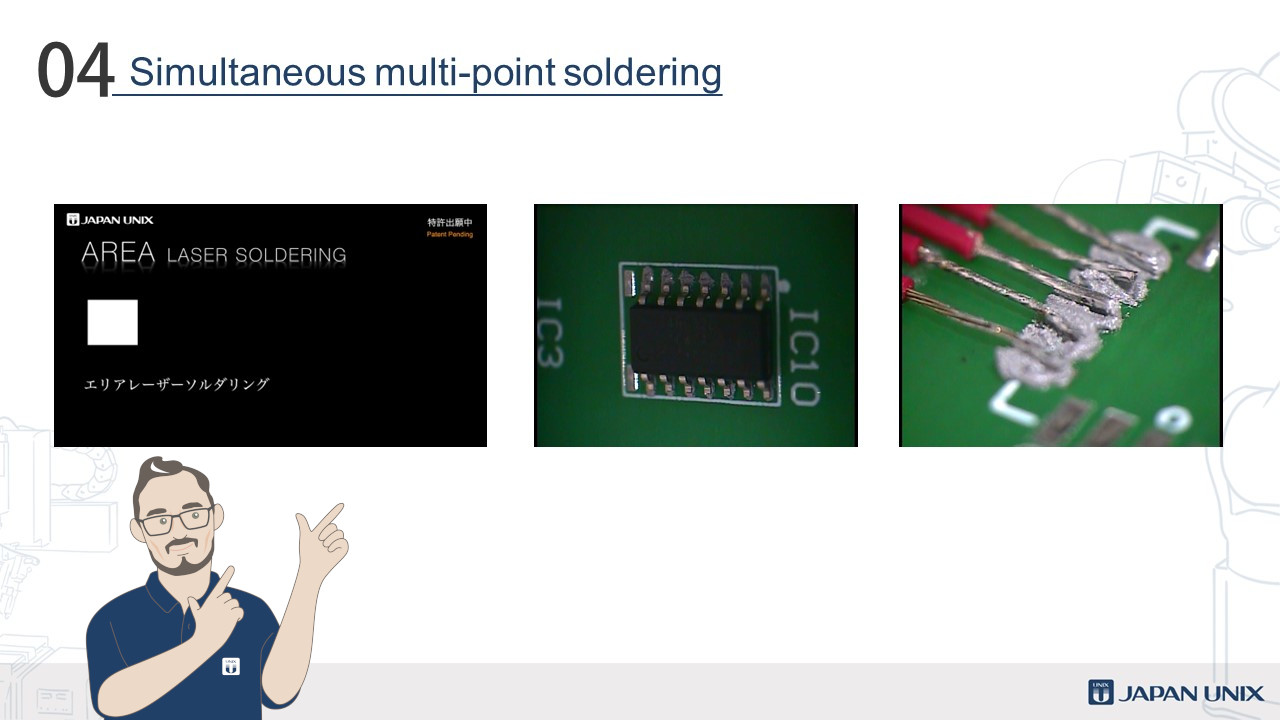

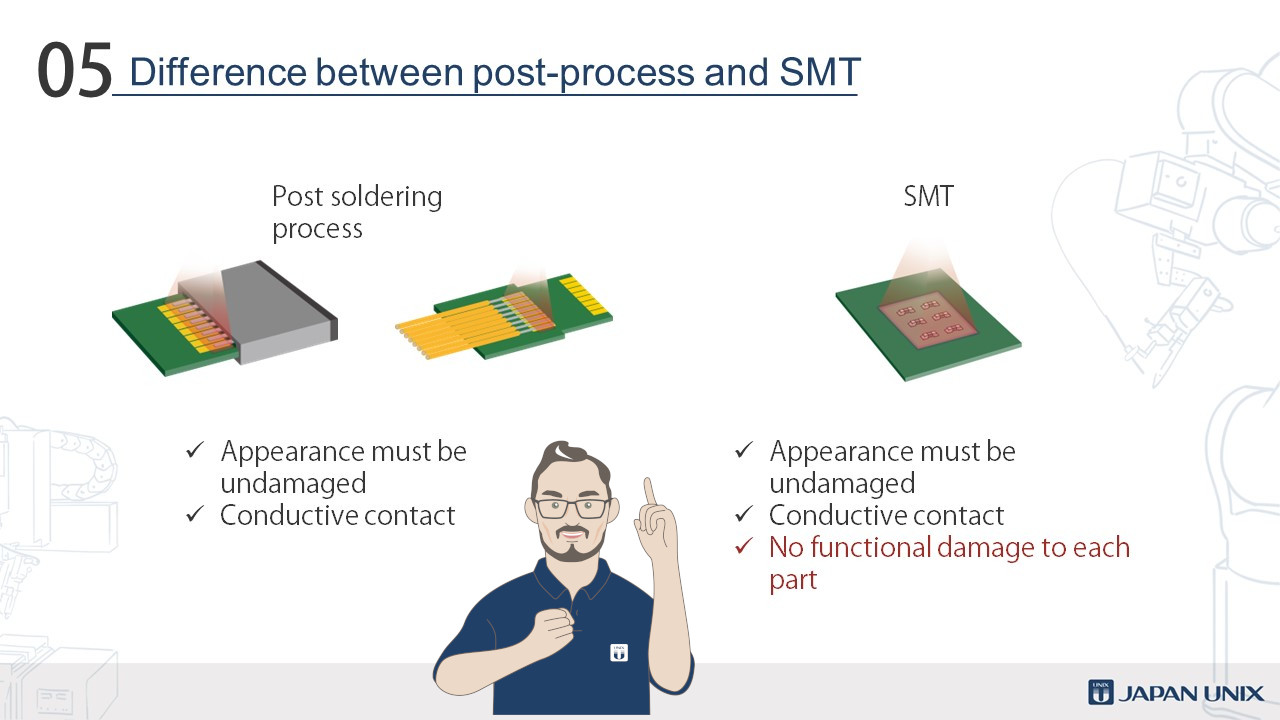

Another significant advantage of the area laser is that it can heat a wide area at once. This makes it applicable not only to the traditional post-process but also to soldering chip components in surface mount technology (SMT). For example, FPC, cables, lead wires, and other components can be soldered at once.

Especially in soldering SMT chips, we have conducted tests with Omron Corporation and confirmed that soldering can be performed without issues in actual products. By using this area laser technology, we can now handle a wide range of applications.

Benefits and Advantages of Area Laser

By introducing area lasers, the cycle time for soldering is significantly reduced. While single-spot lasers solder one point at a time, area lasers can heat multiple points at once. This allows for simultaneous soldering of multiple locations, dramatically improving work efficiency.

Temperature Control and Quality Management

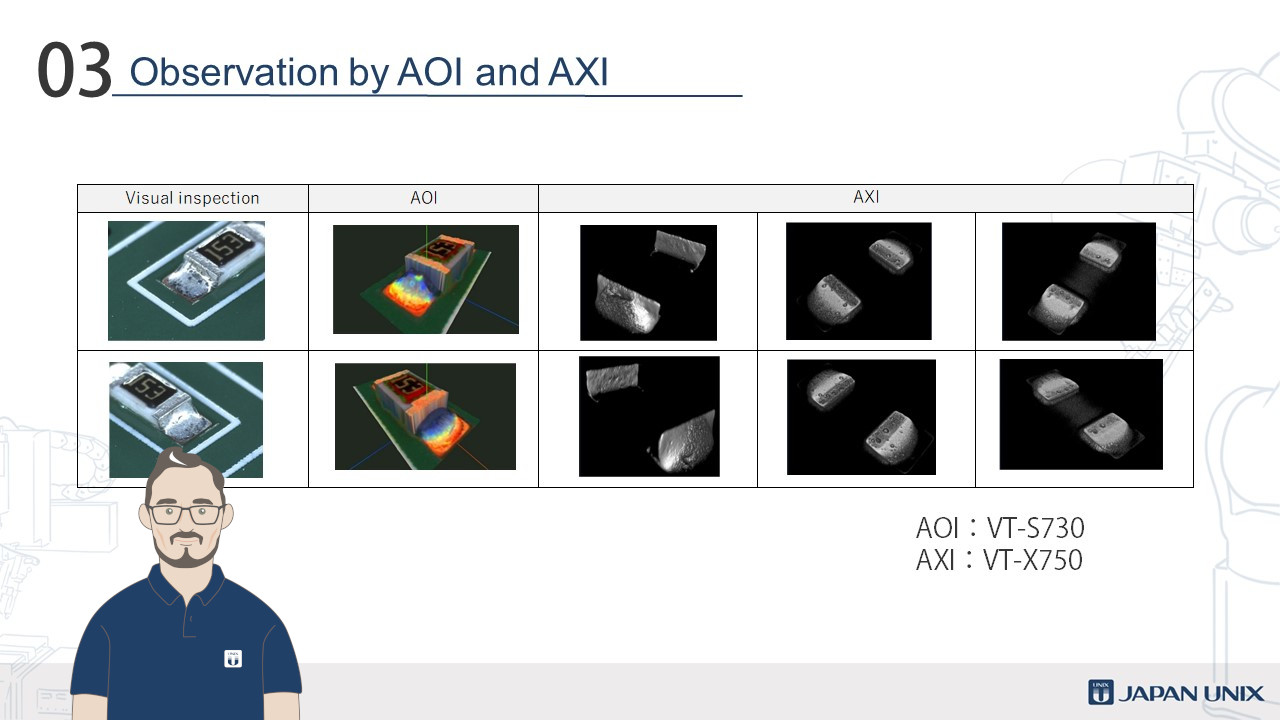

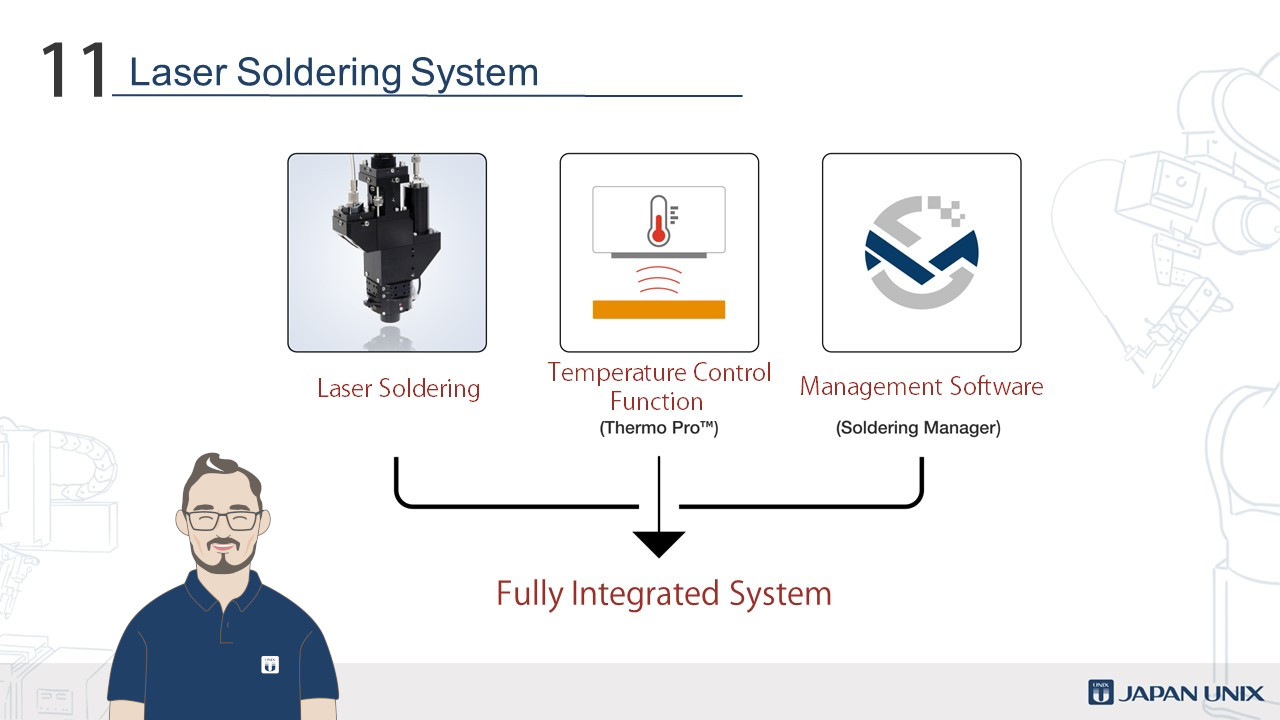

What is important in the introduction of area lasers is temperature control and quality management. By strictly controlling the temperature rise due to laser irradiation, reliable soldering can be achieved while preventing damage to the components. A radiation thermometer is used for temperature control, monitoring the temperature rise due to laser irradiation, and a feedback function is used to control the irradiation output to maintain a constant temperature.

In quality management, it is possible to monitor and record the temperature profile during laser irradiation, allowing for the maintenance of quality control for each product.

Conclusion

In this article, we have introduced the new area laser technology. Through actual examples, we have introduced the unique features of the area laser and its various applications. The introduction of area lasers not only improves soldering work efficiency but also ensures reliable temperature control and quality management, providing high-quality soldering results.

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español