Steve's Tech Article “Maintenance of Soldering Robot”

Steve’s Tech Article!

Maintenance of Soldering Robot

Table of Contents

- Theme

- Condition

- Position

- Tip temperature

- Summary

- Related Products & Services

- Video for this Tech Article

Video for this Tech Article

Theme

S Hello everyone. I am Steve, a soldering engineer at Japan Unix.

Today, I would like to discuss the maintenance of soldering robots.

Maintenance is, in fact, the most common cause of soldering defects.

There are three maintenance points. Let’s examine one by one.

Condition

S The first point is to check the “condition” of the tip.

Flux carbide adhering to the tip can cause heat loss.

To avoid this!

Please use a brush cleaner to sweep it off.

Keeping solder on the iron tip can also help prevent tip oxidation and prolong its life.

Position

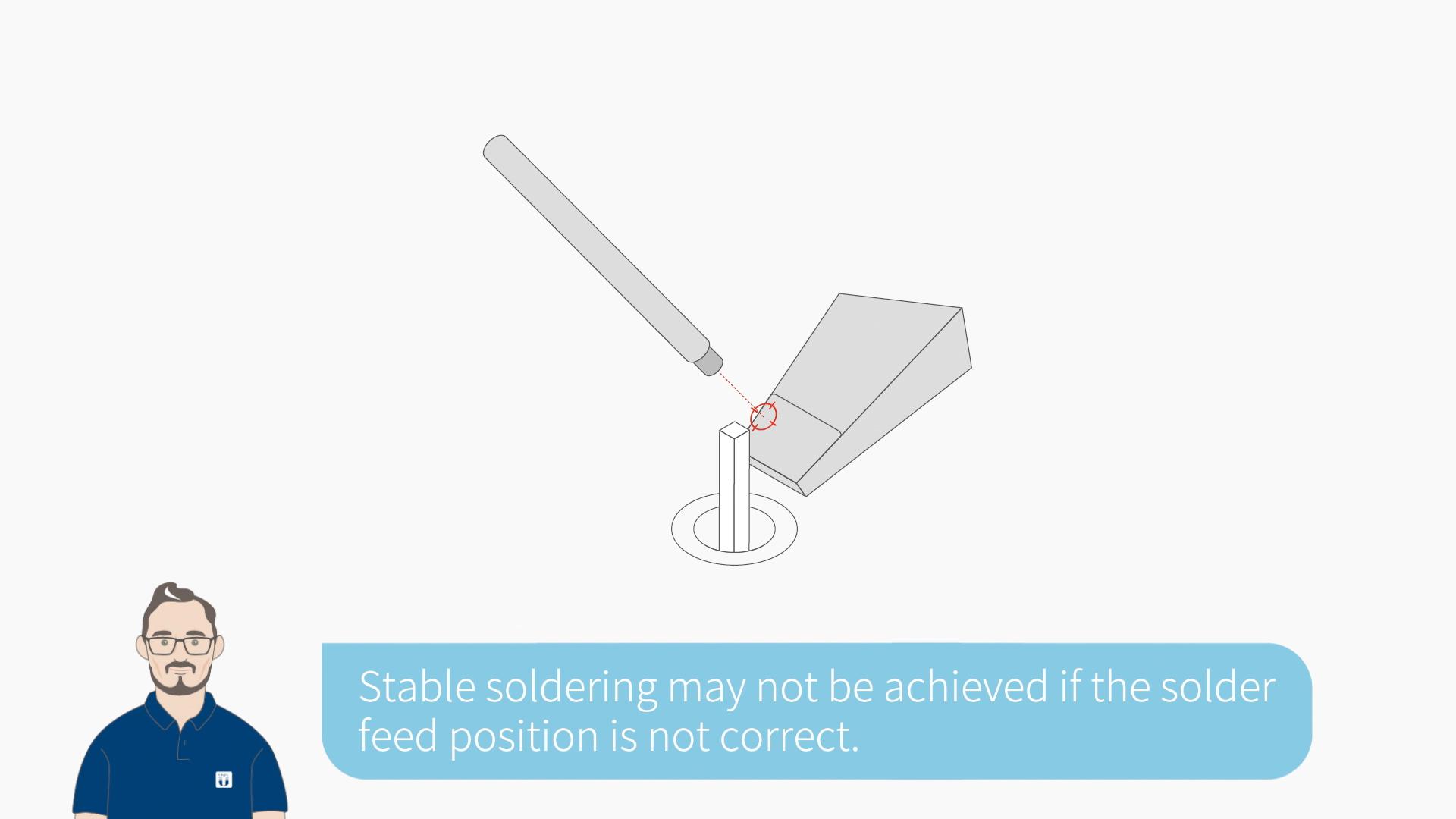

S Second, check the “position” of the solder feed.

Stable soldering may not be achieved if the solder feed position is not correct.

To achieve this!

Please adjust the needle to a fixed position.

This will ensure a stable flow and amount of solder.

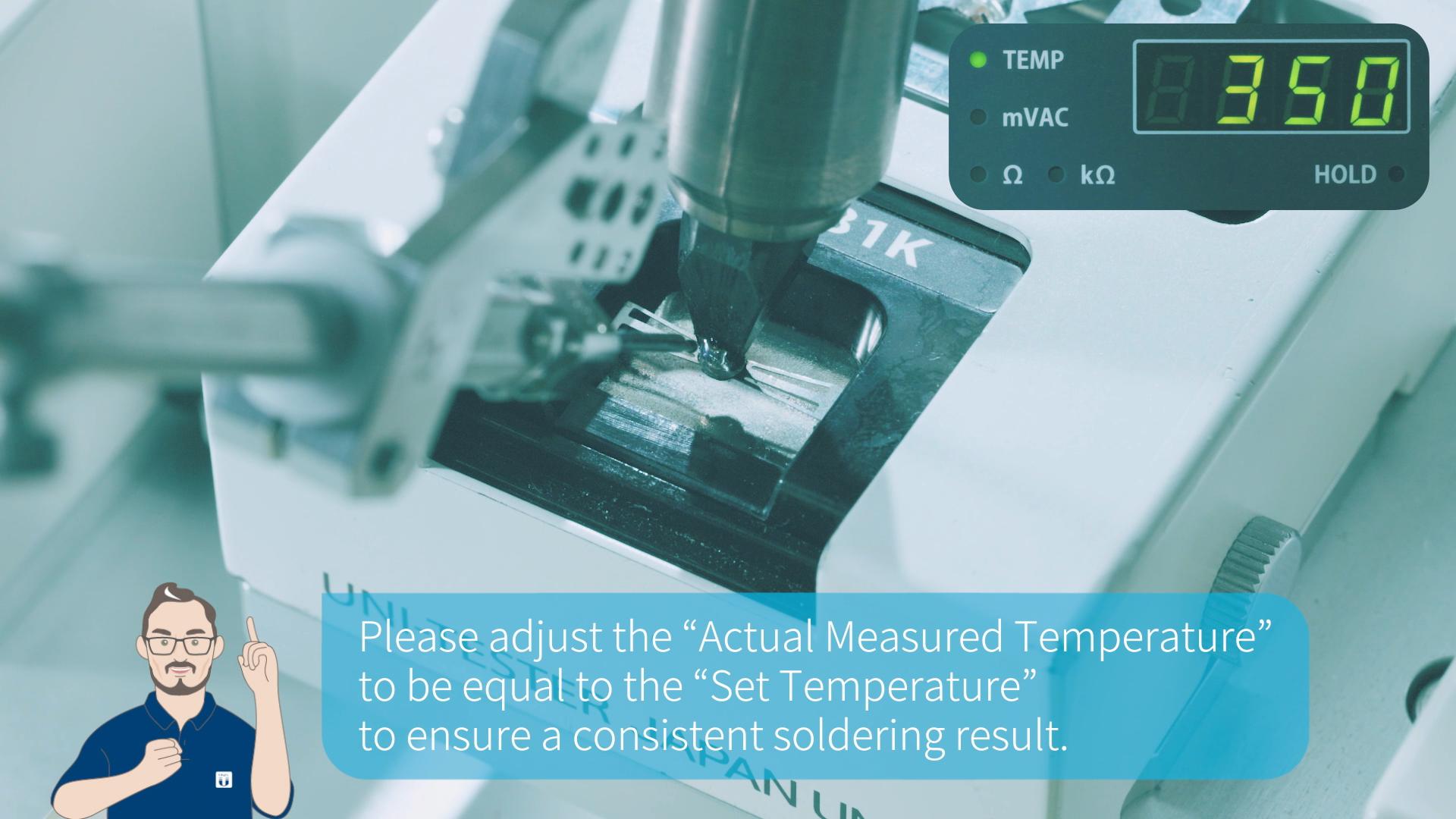

Tip temperature

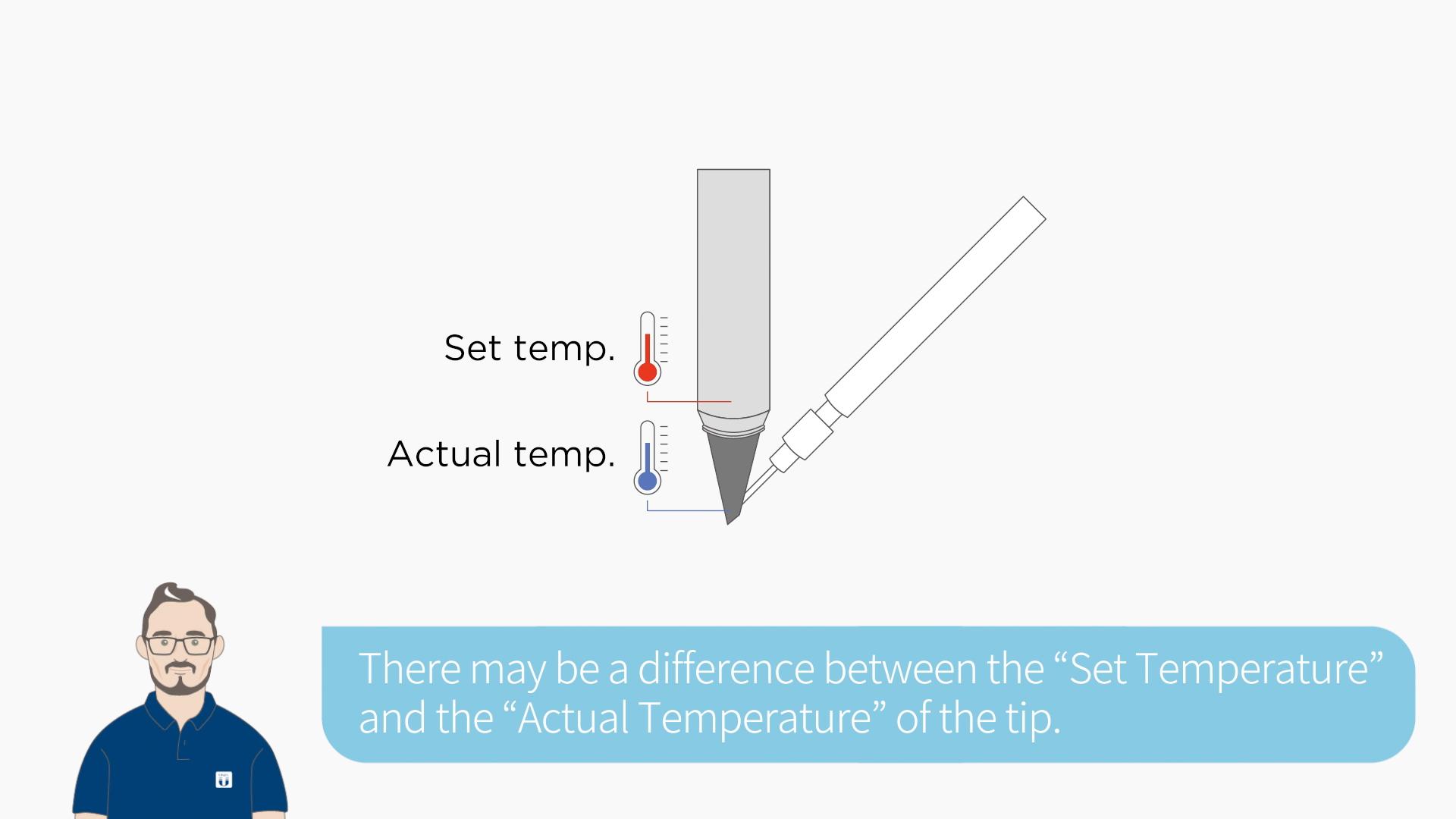

S Finally, check the “tip temperature”.

There may be a difference between the “Set Temperature” and the “Actual Temperature” of the tip.

To achieve this!

Please adjust the “Actual Measured Temperature” to be equal to the “Set Temperature” to ensure a consistent soldering result.

Summary

S For effective maintenance, keep these three key points in mind.

However, the maintenance process might vary depending on the robot’s characteristics and application.

If you have any questions about your specific machine, please contact Japan Unix.

Thank you and see you next time!

Related Products & Services

Video for this Tech Article

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español