Steve's Tech Article “What is a Laser Soldering Robot?”

Steve’s Tech Article!

What is a Laser Soldering Robot?

Table of Contents

- Theme

- Soldering Process

- Heating Principle

- Summary

- Related Products & Services

- Video for this Tech Article

Video for this Tech Article

Theme

S Hello everyone. I am Steve, a soldering engineer at Japan Unix.

Today, I would like to discuss the principles of laser soldering, which have been attracting a great deal of attention.

Japan Unix has been providing this technology to many customers for over 20 years.

Soldering Process

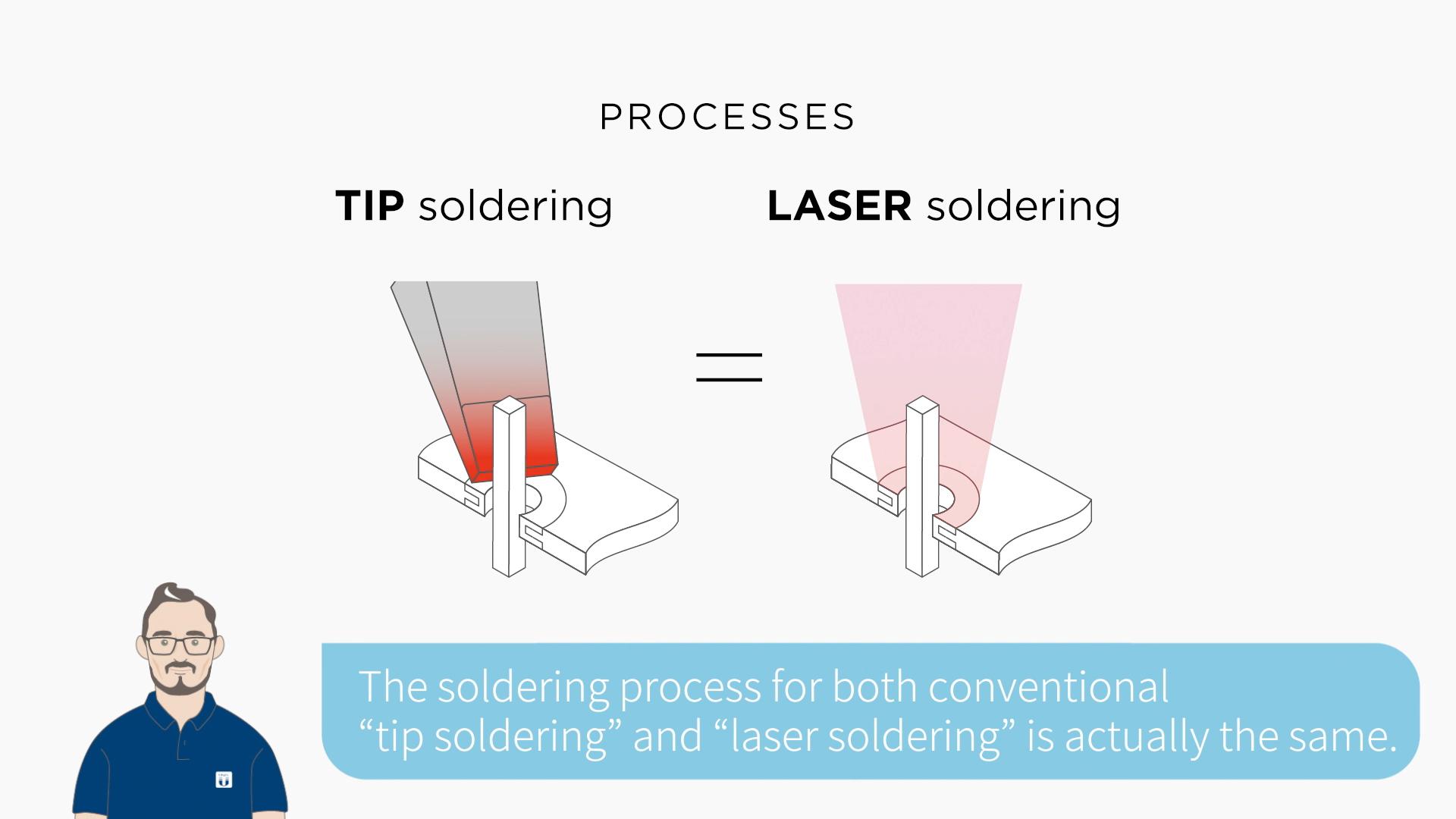

S The soldering process for both conventional “tip soldering” and “laser soldering” is actually the same.

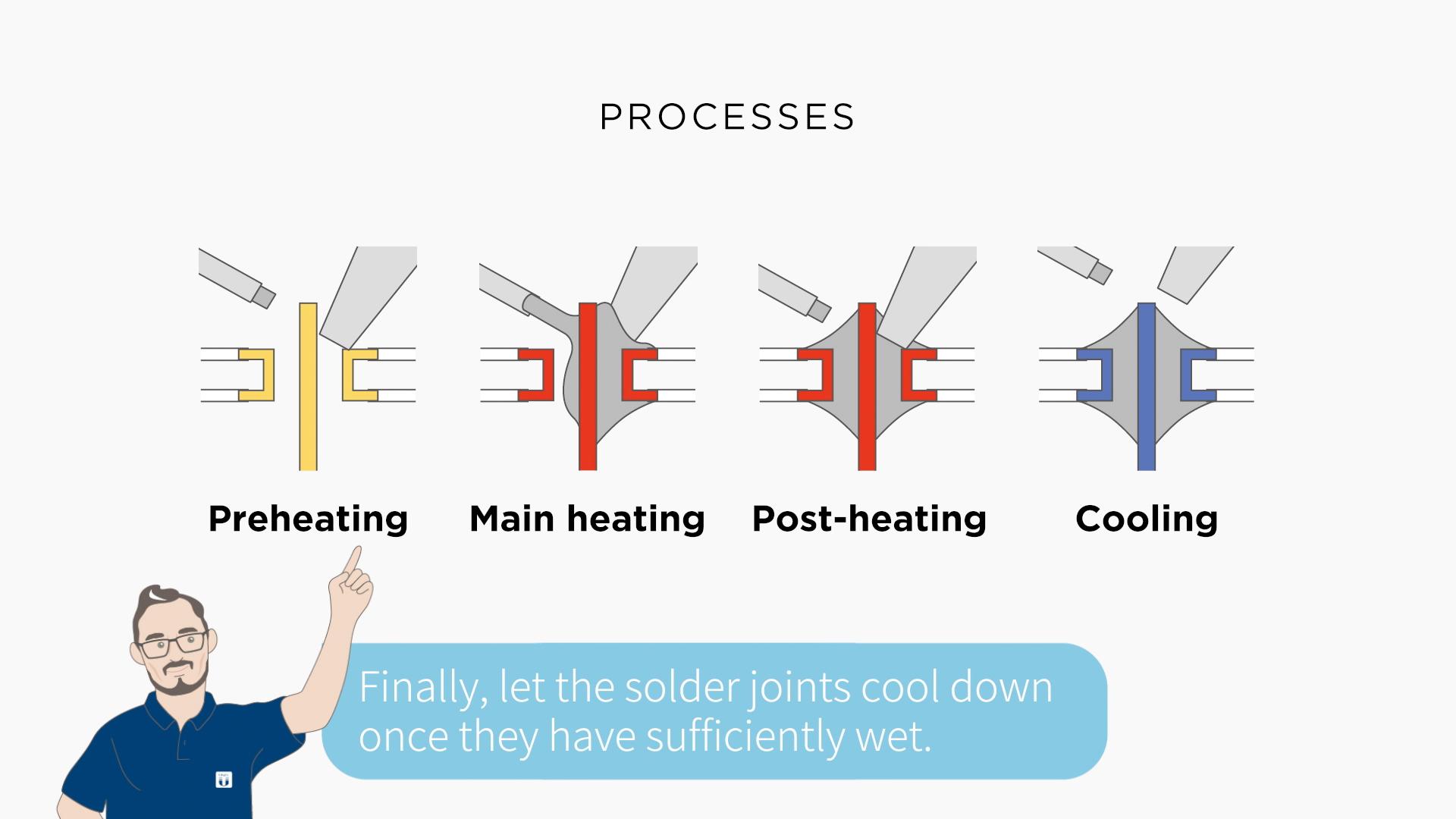

The common soldering process involves four main steps.

First, “preheat” the soldering points to the melting temperature.

Second, supply the solder wire during the “main heating” process.

Third, allow the solder to wet into the hole and around during “post-heating”.

Finally, let the solder joints cool down once they have sufficiently wet.

Now let’s watch some videos.

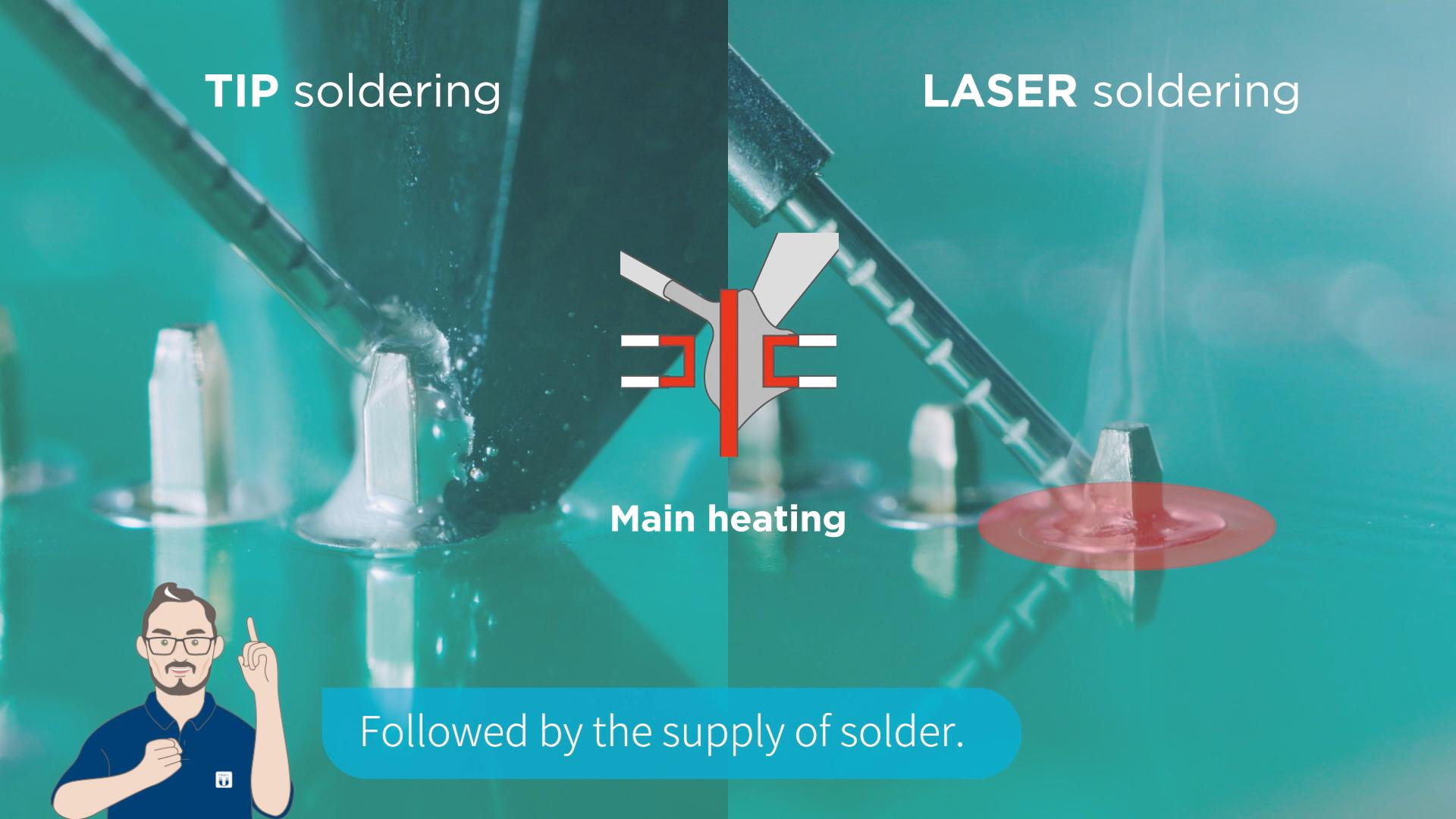

The process starts with preheat. Followed by the supply of solder. Then, the solder spreads. And finally, it is cooled down.

As you can see, the four processes for both “iron tip” and “laser” soldering are essentially the same.

Heating Principle

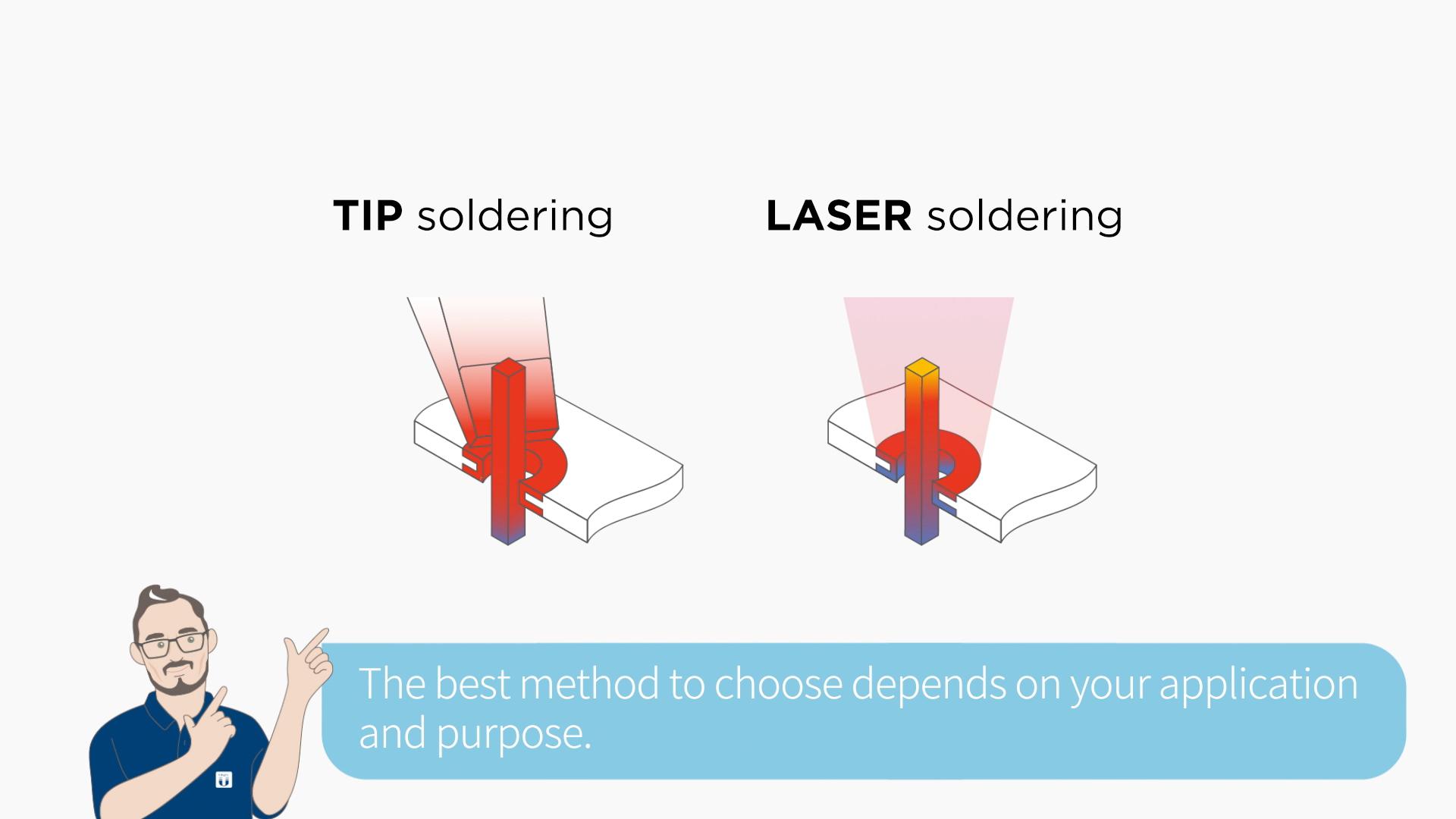

S The heating principle is slightly different.

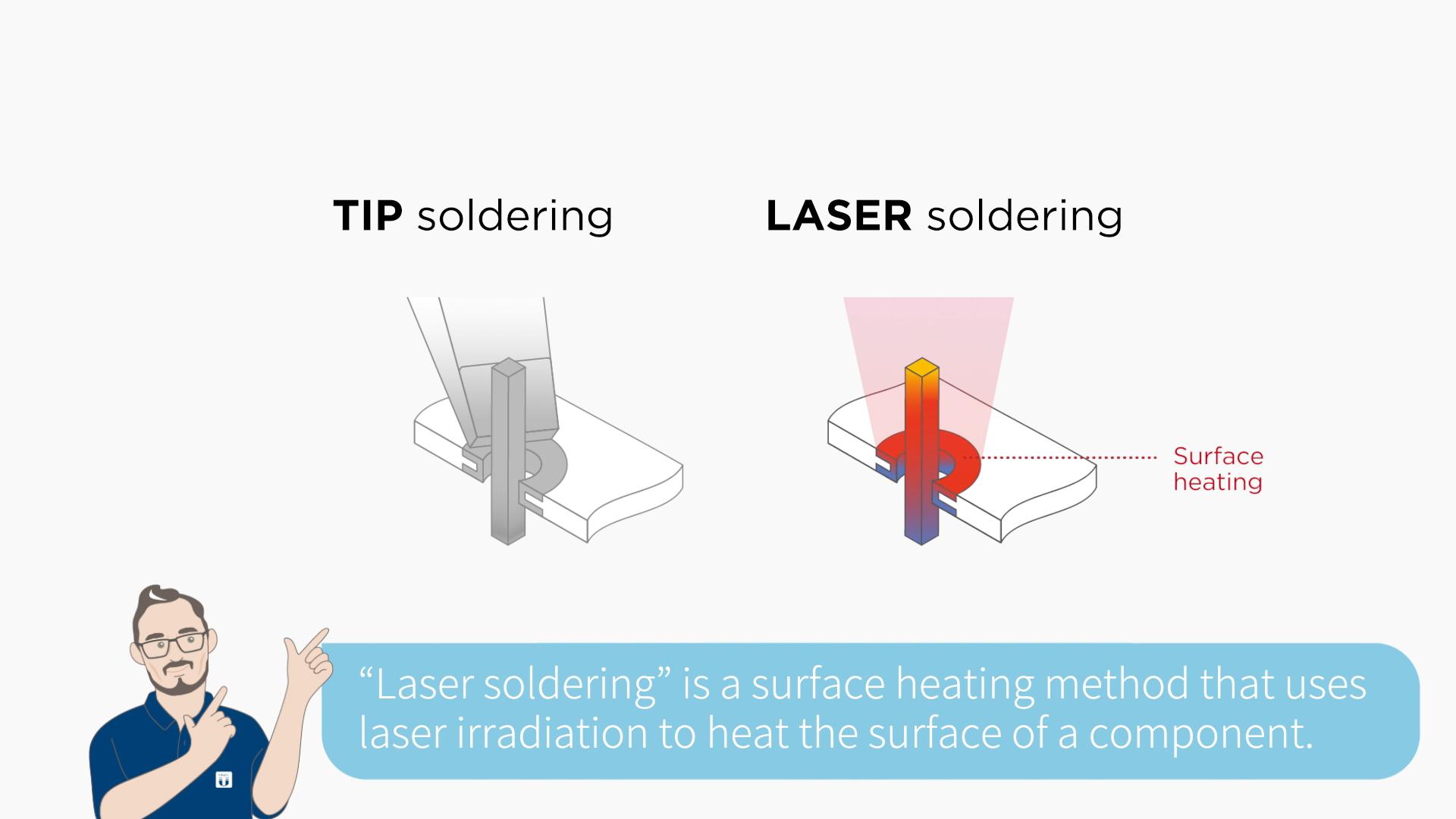

The process of “tip soldering” involves heating components by bringing the tip into contact, making it suitable for gradual and diffusible-heat soldering.

“Laser soldering” is a surface heating method that uses laser irradiation to heat the surface of a component.

It’s suitable for instantaneous and limited heat and space soldering.

Summary

S Neither is superior to the other.

The best method to choose depends on your application and purpose.

If you have any questions about laser soldering, please feel free to contact Japan Unix.

Thank you and see you next time!

Related Products & Services

Video for this Tech Article

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español