Let's Try Soldering! High Heat Capacity - IGBT Tip & Laser

YOUTUBE Article Vol.21!

Let’s try Soldering Series: IGBT

Table of Contents

- Introduction

- Tip Soldering

- Laser Soldering

- Conclusion

- Related Products & Services

- Watch the Video Here

Watch the video for this article here

What is Automatic Soldering of Power Terminals Used For?

Naka Hello everyone. I’m Nakano from Japan Unix. In today’s episode of the “Let’s try Soldering” series, the theme is IGBT soldering. Our guest today is Mr. Yanaka from the technical team.

Ya Thank you for having me.

Naka IGBT power modules are widely used in many automotive components such as EVs and hybrids, which have become quite the topic lately.

Ya That’s right. They are essential for devices that require high power, such as steering and traction motors.

Naka As environmental concerns gain attention, these are important components.

And once again, you’ve conducted tests using both laser and soldering iron tip.

Automatic Tip Soldering of IGBT

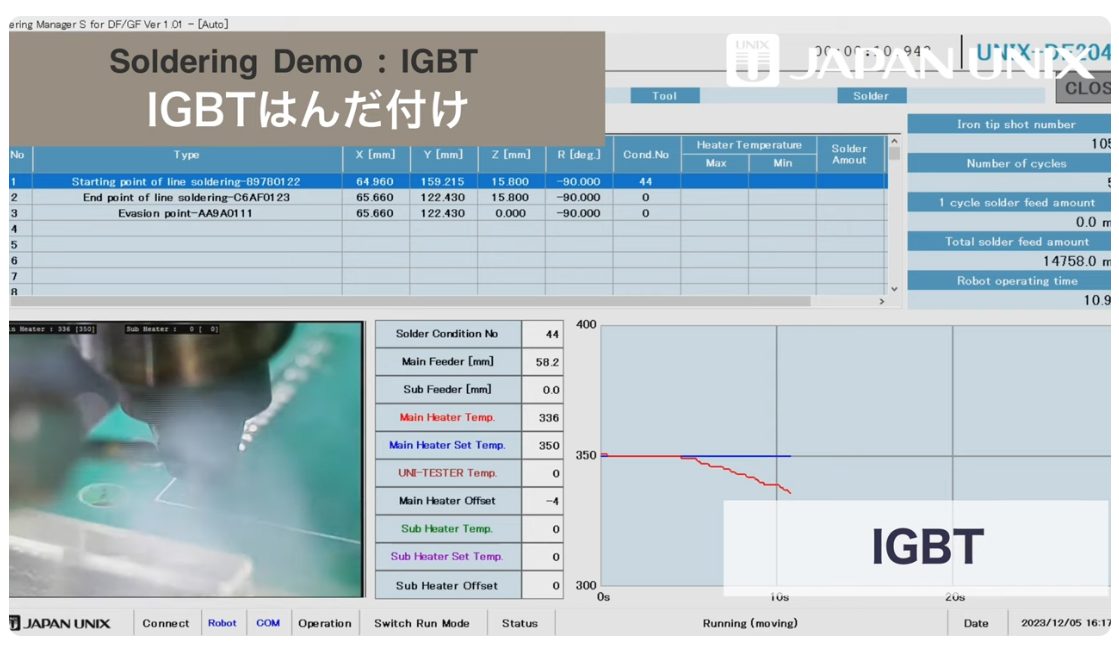

Ya Yes, first we have an experiment video using the soldering tip. Please take a look.

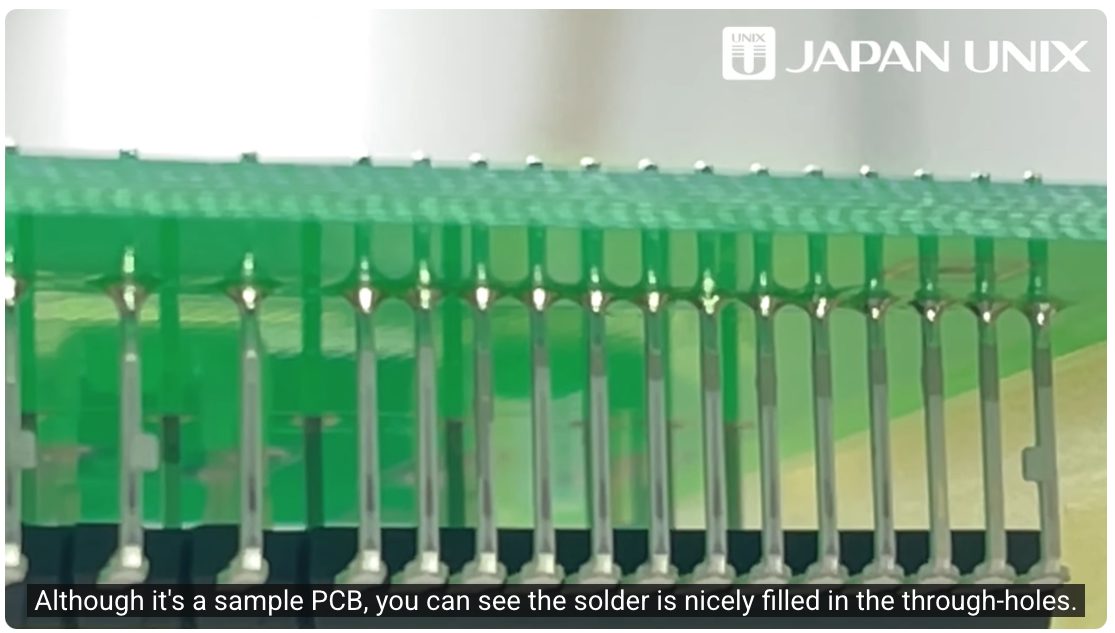

Naka This is the actual soldered product.

It’s just a sample board, but you can see the solder is nicely filled inside the through holes.

Please tell us any key points or characteristics of soldering IGBT boards.

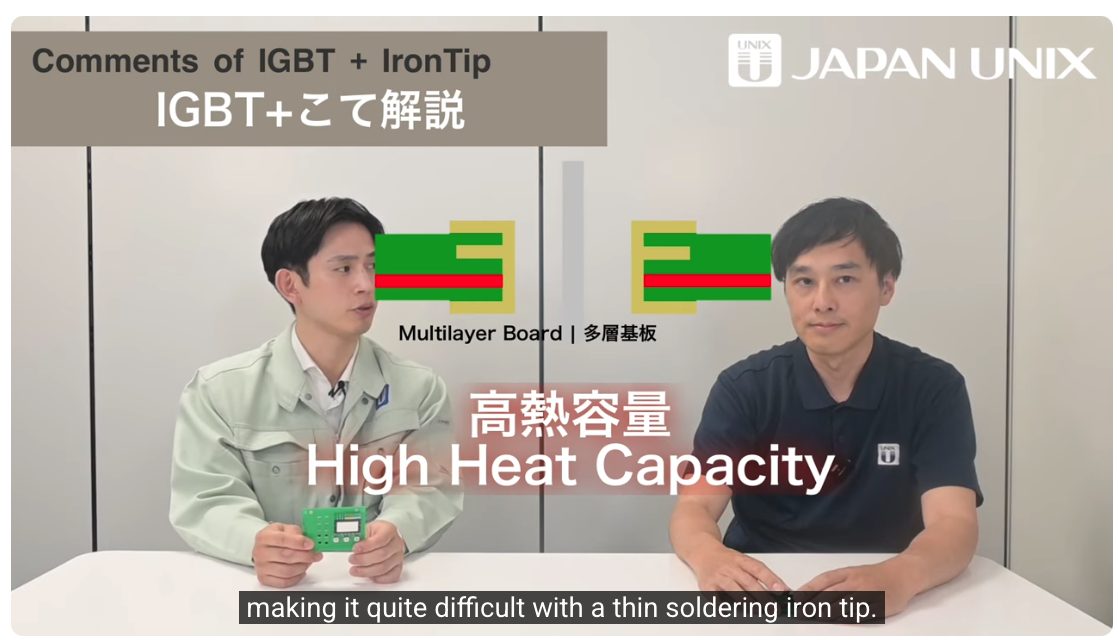

Ya Sure. The main point is that the thermal capacity is very large.

In most cases, IGBT is used with a multilayer PCB connected to large copper ground planes inside, which makes it quite difficult to solder with a narrow soldering tip.

However, if the tip temperature is too high or it remains in contact too long, the flux deteriorates, causing poor wetting or solder spikes. Therefore, careful control of soldering conditions is essential.

Laser Soldering of Power Terminals

Naka Now, let’s take a look at the laser soldering experiment.

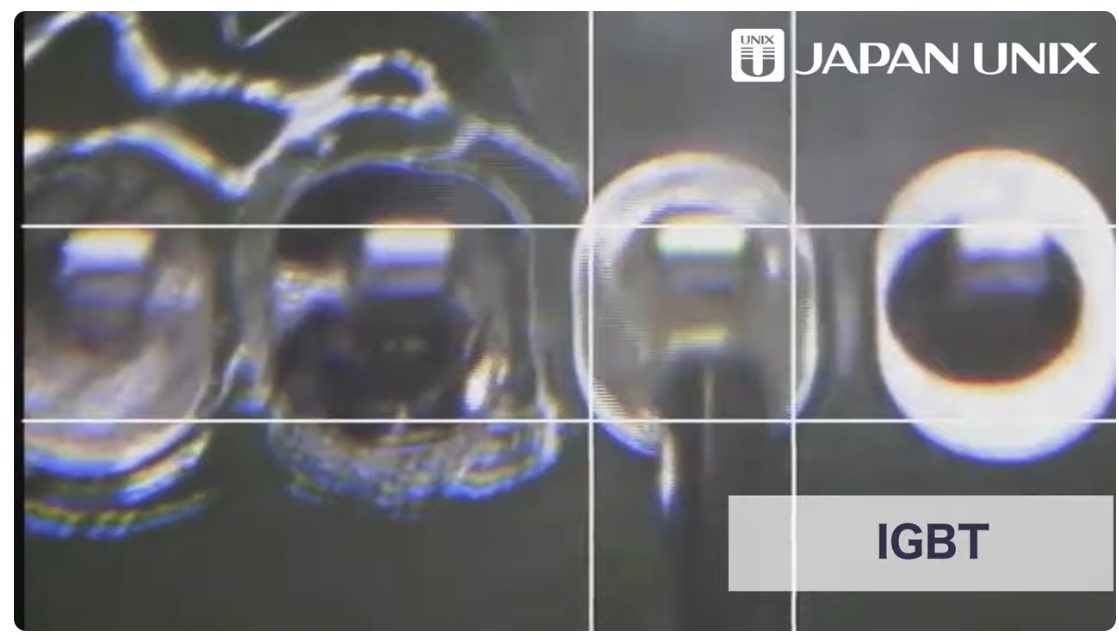

As you can see, the laser soldering was also done very nicely.

Could you tell us about the characteristics and precautions for laser soldering?

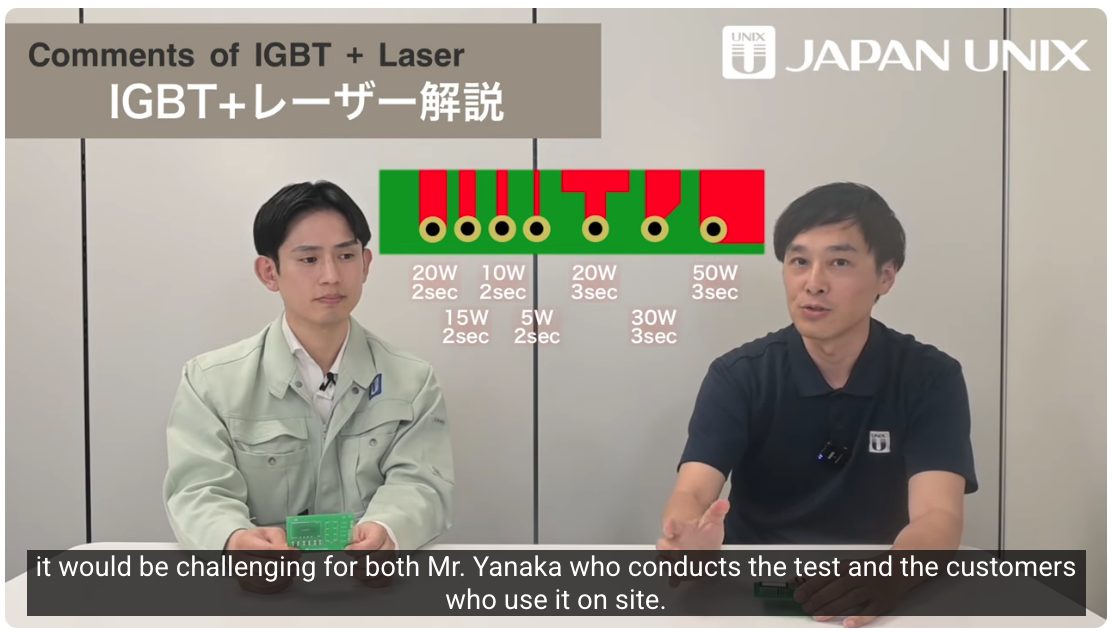

Ya As I mentioned earlier, ground patterns are connected, but depending on the solder point, the circuit structure differs, which changes the thermal capacity.

In other words, the required power and time settings can vary at each point.

Naka If there are many soldering points and each one needs a different set of conditions, that must be challenging both for you during testing and for customers during operation.

Ya That’s why, whether using a soldering iron tip or a laser, we always consult with customers from the PCB design and prototyping stages to offer proposals that facilitate easier mass production management.

Conclusion

Ya In soldering, adjusting the soldering conditions is a very important factor.

We are fully committed to supporting that aspect, so please feel at ease.

Naka Thank you very much for your explanation today, Mr. Yanaka.

Ya Thank you very much.

Naka See you again in the next video!

Related Products & Services

Watch the Video for This Article Here

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español