Basic Knowledge of Soldering Technology Vol.2 “Laser Soldering”

While laser soldering has many advantages such as no physical load, the procedure requires a high level of skill and experience. It is important to use different soldering methods from iron soldering depending on the purpose.

New Soldering Methods

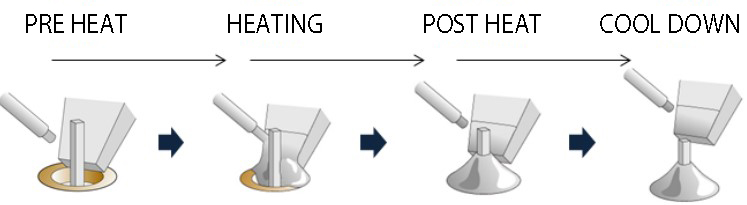

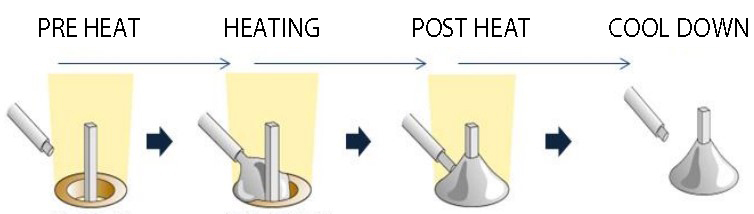

Laser soldering is a new process that differs from iron tip soldering in its heating principle. The three steps of soldering are the same: “preheating” to warm the area to be soldered, “heating” to feed wire solder, and “post-heating” to shape and finish the area, but the heat conversion theory is different. In iron tip soldering, a heated iron tip is applied to the soldering point to raise the temperature, whereas in laser soldering, the area irradiated by the laser itself generates heat (surface heating).

In the case of iron tip soldering, the temperature basically does not rise above the set temperature, and the amount of heat transferred to the surrounding area is determined by the time the iron tip is applied. In laser soldering, on the other hand, the area exposed to laser irradiation generates limited are heat, and the temperature rises instantaneously according to the amount of energy absorbed, so there is a risk of overheating. Therefore, laser soldering requires a high level of skill and experience in adjusting irradiation energy and time.

Process of Iron Tip Soldering

Process of Laser Soldering

Features of Laser Soldering

(1) Non-Contact, No Physical Stress

Soldering can be done without any physical stress by simply irradiating the laser and feeding solder, without touching the board and any electronic components.

(2) Pinpoint soldering is possible

Since it can efficiently heat with pinpoint accuracy, it is suitable for soldering in tight spaces where an iron tip cannot approach, or in high-density mounting where components are almost in close contact with each other.

(3) Easy to automate

Efficient heating and solder feeding facilitate automation and stable soldering.

(4) High maintainability

There is no need for periodic tip cleaning or replacement, and fewer consumables are required.

Select the method that best suits your purpose.

Laser soldering is not a replacement technology for iron tip soldering, but a different process with a different heating principle. Each has its own strengths and weaknesses, so simply replacing iron tip soldering with laser soldering because it is a new technology may erase the advantages of laser soldering. It is important to take advantage of the characteristics and strengths of each, and complement and use them differently depending on the application.

Points to consider when choosing soldering with iron tip soldering or laser soldering

| Iron Tip Soldering | Laser Soldering |

|---|---|

| ✔Good at high thermal capacity parts | ✔Good at high thermal capacity parts |

| ✔Easy temperature control during fat soldering | ✔Soldering in tight and complicated places is possible. |

| x Cannot be used in narrow places where the tip of an iron cannot fit or for high-density mounting. | x Irradiation energy and time must be carefully adjusted. |

If you would like to know more about the principle of “laser soldering,” precautions when using it, and the effects of excessive heating on solder and pcb, please click here to download the PDF file.

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español