Case Study Interview: Production Engineer with 40 Years of Experience – Part 2

Case Study Interview

Production Engineer with 40 Years of Experience – Part 2 –

Table of Contents

- What happened in the 2000s?

- Reproducing Skilled Workers’ Techniques with Laser Soldering

- Tips for Smooth Robot Implementation in the Company

- Robot Implementation Is Just the Starting Point: The Importance of Continuous Operation

- Advice for the Next Generation of Production Engineers

- Reference Video for This Topic

Shift to Automating Difficult Tasks with Robots in the 2000s

Bamboo skewers are thin but hard, inexpensive, less likely to damage components, and less prone to static electricity, making them a popular tool in electronics manufacturing even today in Japan.

Bamboo skewers are thin but hard, inexpensive, less likely to damage components, and less prone to static electricity, making them a popular tool in electronics manufacturing even today in Japan.

What happened in the 2000s?

After the 2000s, major production bases were relocated overseas, and the main tasks increasingly involved maintenance and modifications of equipment that had already been developed and installed into production sites. As a result, efforts began to automate the “craftsmanship of skilled artisans” as an advanced production technology using robots.

Until then, production equipment focused on automating high-speed, high-quality soldering to mass-produce high-margin products. However, with production shifting to overseas locations, the tasks that remained on domestic production lines were those that required skilled workers to perform difficult operations. These tasks often became bottlenecks in production, so significant efforts were made to automate them and pass on the necessary technical expertise.

For example, cables and harnesses extending from sensors consist of multiple thin wires bundled into a multi-core cable. In the manufacturing process, the outer sheath and each individual wire need to be stripped, and the wires must be placed in the designated positions on circuit boards or connectors for soldering. Core wires are thin and flexible, and may bend slightly when stripped, making this process more complex than the soldering of electronic components onto circuit boards, where each part is placed in a fixed position. Despite these challenges, quality had to be maintained, making automation difficult. As a result, human workers continued to be relied upon.

Skilled operators not only mastered the use of soldering irons but also skillfully handled various tools such as bamboo skewers and tweezers. Their craftsmanship was truly remarkable.

Reproducing Skilled Workers’ Techniques with Laser Soldering

So, you have been working on automating such difficult tasks?

If the assigned worker leaves, production will come to a halt, and if orders increase, production volume cannot be scaled up. Therefore, we worked on standardizing and automating each task.

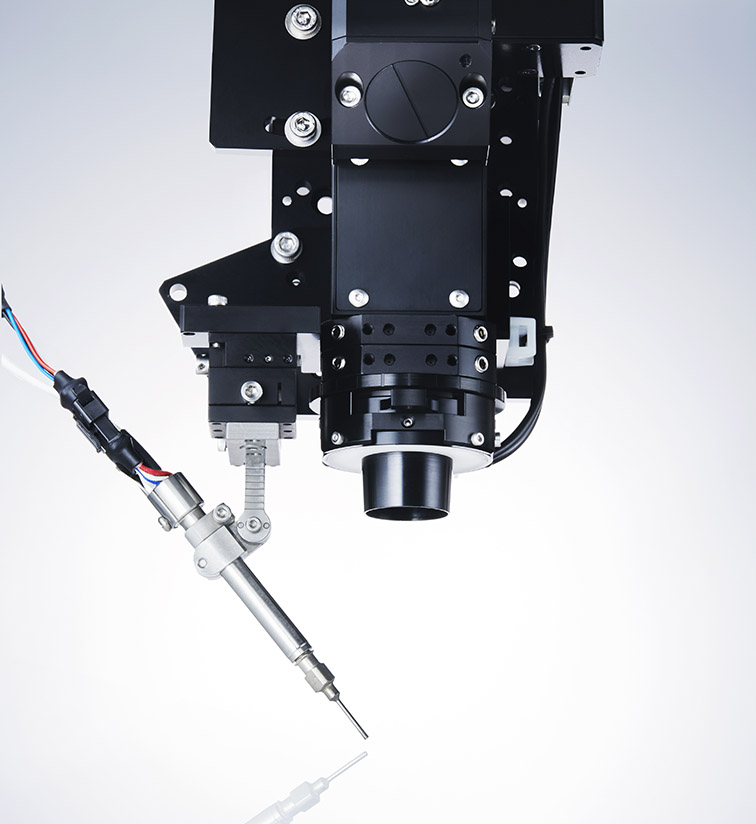

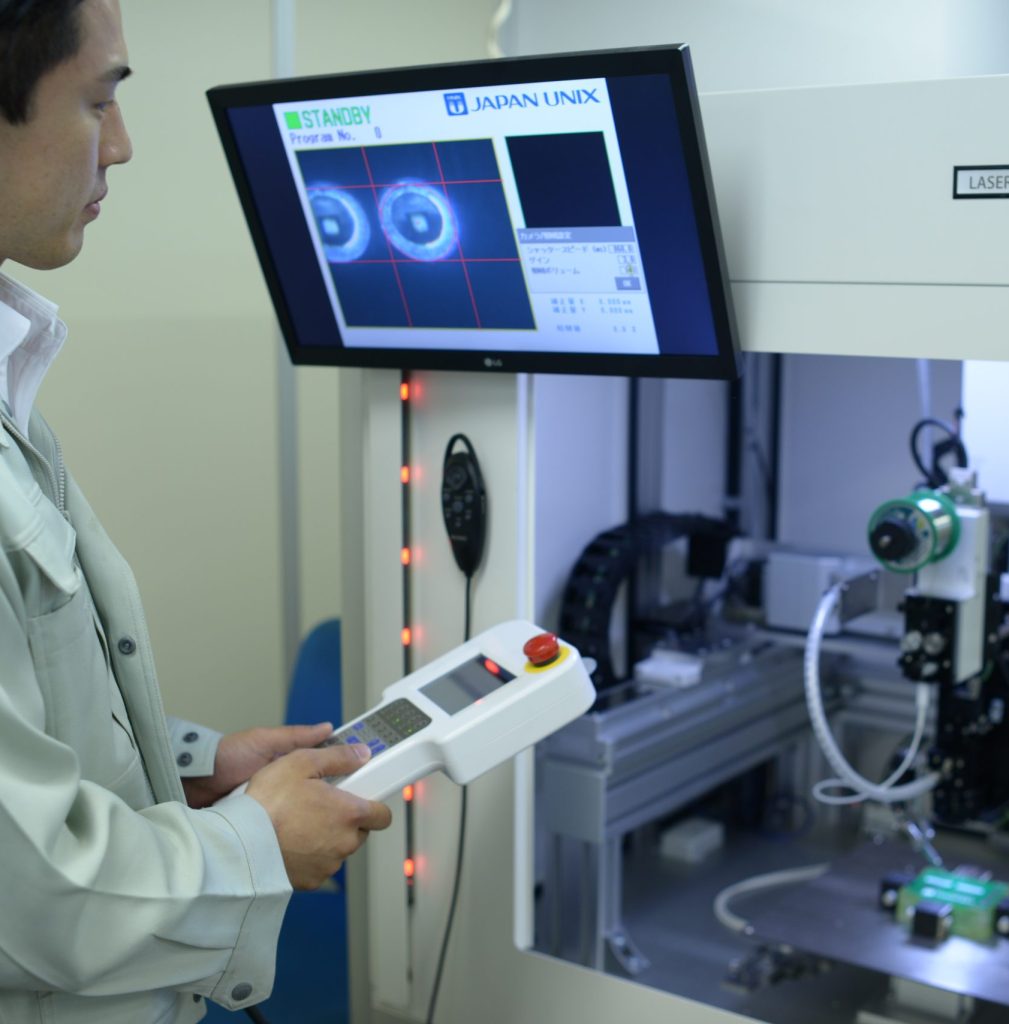

With the cooperation of Japan Unix, we developed a prototype. We adopted laser soldering for the first time, using a camera to recognize components and extracting conditions based on information from previous and subsequent processes, thereby achieving soldering automation.

The reasons we chose Japan Unix’s laser soldering were their long-standing achievements and reliability in soldering equipment, as well as their excellent temperature management and control functions. The measured temperatures are displayed in graphs with high accuracy. Since temperature control is crucial for soldering, we found their deep knowledge of soldering technology to be highly valuable.

Tips for Smooth Robot Implementation in the Company

How can robot implementation be carried out smoothly?

Even if a manufacturing site wants to install soldering robots, managers and executives are often concerned about the cost-effectiveness and return on investment (ROI) of the equipment. A simple proposal that just divides the investment cost by production volume to show ROI is weak because it does not address the real problems faced in the field or their solutions.

It is important to break down the investment effects in detail and demonstrate the benefits from various perspectives. For example, while dedicated machines become obsolete when production of a specific product ends, robots can be repurposed for different product lines simply by changing their programming.

Additionally, in today’s labor market, hiring and training workers is becoming increasingly difficult. Robots can help solve these challenges, making it beneficial to highlight these advantages when making a proposal.

Robot Implementation Is Just the Starting Point: The Importance of Continuous Operation

Are there any key points to be aware of after implementation?

Soldering robots are not just about implementation; the key is how to keep them running efficiently to generate profits over the long term.

This requires daily maintenance, periodic part replacements, and regular overhauls as a minimum requirement. However, in practice, ensuring consistent maintenance is quite challenging. Even when maintenance instructions are given, they are often not followed, leading to accumulated damage to the machine.

One effective strategy I implemented was to show production line operators real data on the relationship between soldering conditions, soldering iron tip wear, and defect occurrence mechanisms. By explaining the reasoning behind maintenance manuals and guidelines carefully, I helped them understand that a little daily effort improves yield rates, ensures production stability, and prevents sudden machine failures.

As a result, maintenance became a routine part of daily operations, ultimately extending the lifespan of the equipment.

Advice for the Next Generation of Production Engineers

Looking back on 40 years, what advice do you have for the next generation?

The 1980s and 1990s were eras where mass production was the key to success. Later, production bases were relocated overseas, particularly to China, and domestic manufacturing shifted to small-lot, high-mix production, only producing batches that were just barely profitable. This situation has made new equipment investments more challenging.

Despite these circumstances, companies must continue to exist, and it is crucial to pass down technology and skilled engineers to the next generation. However, given the difficulties in hiring new personnel today, I believe our role is to enhance product value and reduce costs through the use of robots.

The key is not just to focus on mass production, but to design high-margin products and develop efficient manufacturing processes for them. When mass production is needed, it can be handled at overseas factories, while domestic facilities should be established as mother factories and research & development centers. In the field of production engineering, utilizing robots is now an indispensable approach.

Related Products and Services

Reference Video

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español