[Challenges for Local Manufacturers] The Secret to Trust and Growth Through Strategic Equipment Investment

Taking Initiative to Implement Automated Equipment

A young company located in the Tohoku region and led by Representative Director A is a relatively new company, established about 10 years ago. Despite its short history, the company has established itself as a trusted contract manufacturer of cable harnesses, receiving early consultations from domestic and international electronics and semiconductor manufacturing equipment companies regarding new products and facilities.

Through proactive investments in soldering robots and other automated equipment, they stay ahead of industry demand, building advanced technical capabilities at an early stage, and solidifying trust with their clients.

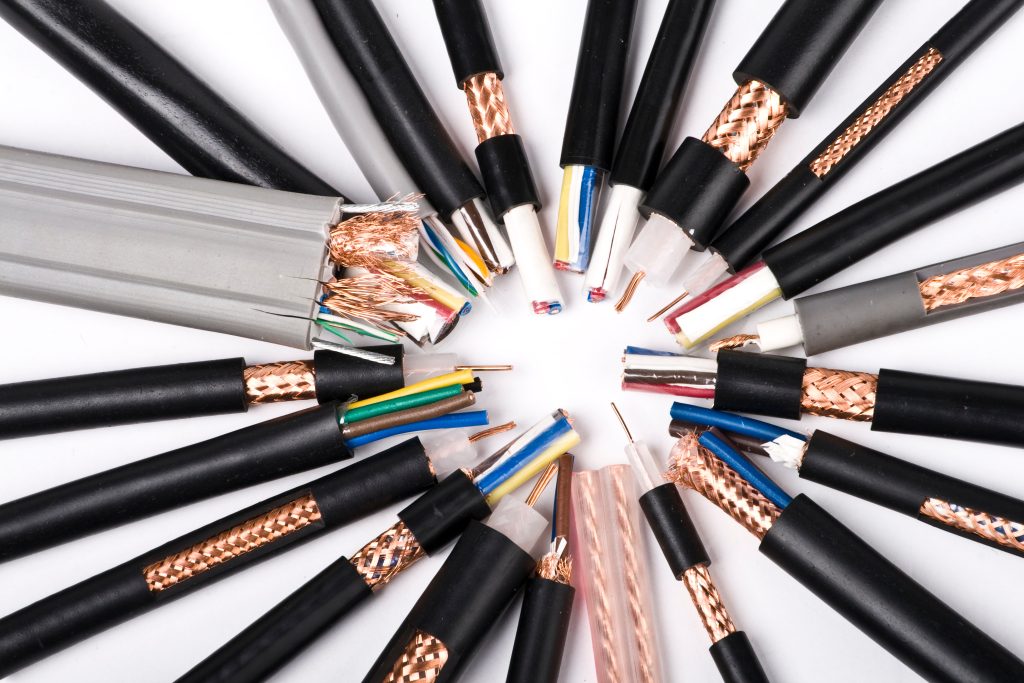

Skilled in High-Difficulty Industrial Special Cable Manufacturing

Coaxial Cable

Tell us about your company

Our company was established in the early 2010s and specializes in processing special wires, cables, and harnesses. Headquartered in the Tohoku region, we are a small organization with just over 20 employees, but we place great importance on improving our skills and embracing challenges every day.

Our primary products are coaxial cables, multi-core cables, and special cables for data communication, many of which are high-difficulty items to process. We excel in producing high-spec cables for semiconductor-related equipment.

Our clients include many large corporations, and we collaborate on everything from prototyping and idea stages to mass production. Typically, cable and harness manufacturers find it difficult to respond to small prototyping requests, but we actively tackle even the most challenging cases, serving as a partner to resolve our clients’ issues. Customers often turn to us for manufacturing solutions they cannot handle in-house, and we work together to explore processing methods, strengthening our capability to handle difficult challenges. We aim to live up to our reputation as the “company of last resort.”

Initially Repaired and Used Secondhand Machines

Your company has been around for only about 10 years?

Previously, I worked for a subcontractor of a major manufacturer, producing connector cables for specific industries. However, due to the subcontractor reducing domestic production and the impact of the 2011 earthquake, continuing the business became difficult. At that time, one of our main clients requested that we continue production, and with the support of an acquaintance’s company, we took over the business. After stabilizing the operations, we established the cable and harness contract manufacturing as an independent business, which continues to this day.

How did you manage to set up a factory and equipment?

Although we started the company, we had no equipment and started from scratch. Since we couldn’t afford new equipment, we gathered used machines for wire processing with the help of clients and manufacturers, gradually building a functional factory.

At that time, we heard that a major client wanted precise cable processing using laser equipment. In 2015, we introduced a YAG laser jacket cutter. Of course, we couldn’t afford a new laser system, so we sourced a secondhand one, repaired the broken parts ourselves to reduce costs, and made it work. It was a significant investment for us and a big gamble, but owning and mastering the laser processing equipment earned us the trust of our clients and secured orders. Later, we added a CO2 laser system, which led to increased orders.

Preparing Equipment and Technology Ahead of Customer Demands

You seem to be heavily focused on facility investments at your site

Our customers want to work with companies that can deliver high-quality products consistently and reliably.

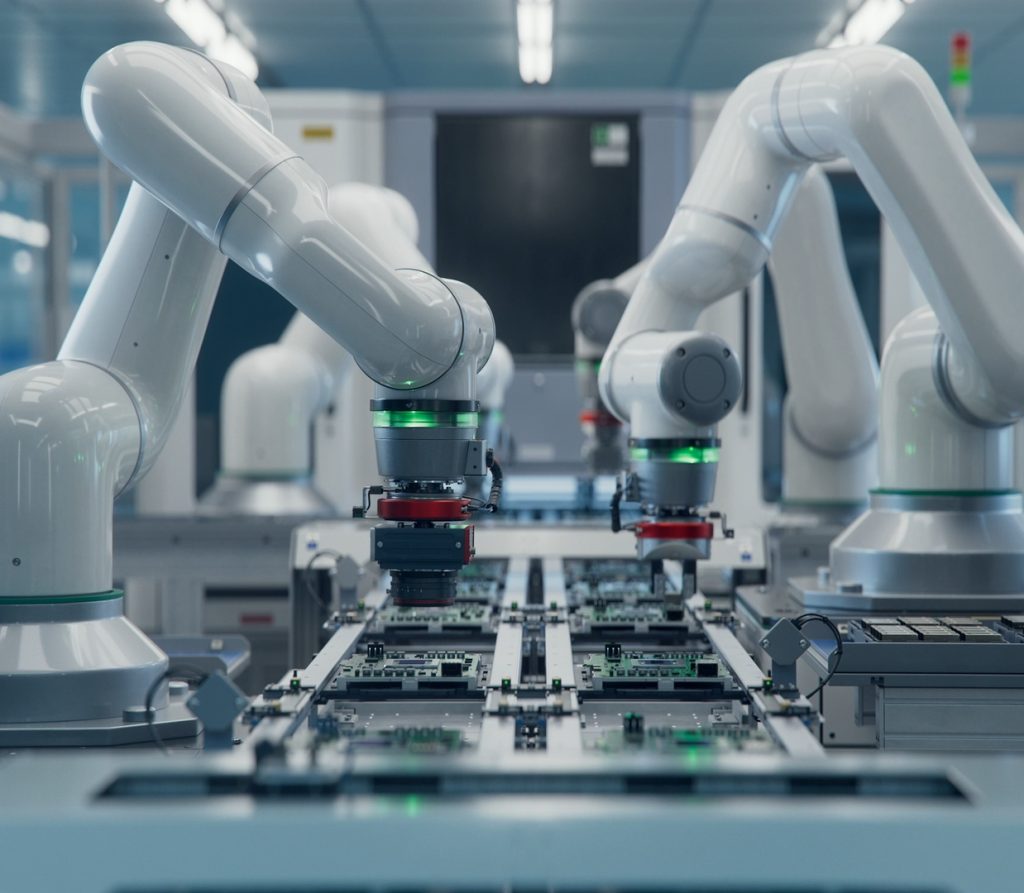

While existing equipment can handle conventional mass-produced items, the reality is that customers are looking for solutions for new products and the next stages of development. When moving into new territory, can a company relying on old equipment and specific skilled technicians really provide added value? By proactively investing in new equipment and tackling automation and labor-saving measures, we strive to prepare ahead of customer demands. This is one of the efforts we make to be ready to participate in business negotiations, focusing on significant annual equipment investments.

Automating Precision Soldering Once Dependent on Skilled Labor

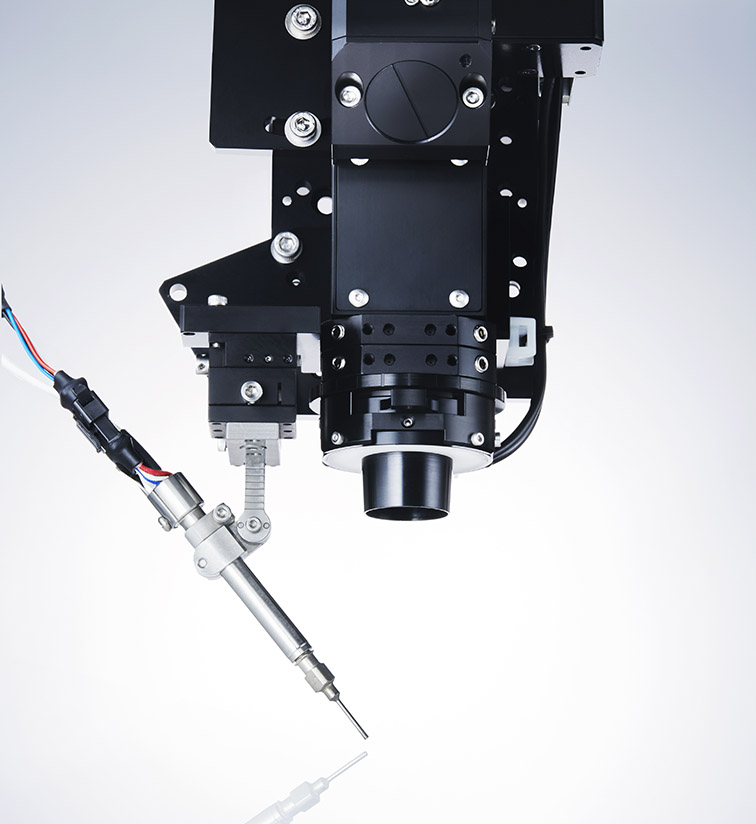

Tell us about the introduction of Japan Unix’s soldering equipment

Pre-processing tasks like wire cutting and stripping in cable and harness manufacturing were automated using laser processing systems. Next, we wanted to automate the soldering process, which relied heavily on veteran employees. We visited the InterNepcon Japan exhibition to explore soldering robot booths. After observing various demonstrations, we were convinced that soldering robots could handle our soldering processes. We handed over our workpieces to Japan Unix for testing, reviewed the returned samples, and decided to proceed with the implementation.

However, at that time, our existing setup was able to meet production demands, and the robots remained unused for a few years. Later, as production volumes increased, we finally introduced the robots into our actual operations.

What prompted you to adopt soldering robots?

Labor shortages were severe then and remain so now. Even when we hired soldering technicians, it took time before they were ready to handle our complex, high-difficulty tasks. Hiring has become increasingly challenging. Automating soldering with robots allowed us to avoid hiring new personnel and reassign existing staff to other tasks.

Additionally, there were concerns from clients regarding our resources and production capacity when it came to high-volume orders. Some deals were even lost due to these concerns. These factors reinforced the necessity of automation centered around robots, which led to our decision to adopt them.

Visible Effects: Increased Productivity and More Project Inquiries

Actual soldering robots

What were the effects of implementation?

Improved production efficiency and enhanced adaptability to fluctuating demand were significant benefits. For one cable order requiring 20,000 core wires bundled in sets of three, the soldering process involved 60,000 points. Given the complexity and precision required for this narrow soldering task, only trained staff could handle it. However, with the current labor shortage, even if we hire someone, it takes time to train them for practical application.

Robots, on the other hand, can consistently perform the same tasks with uniform quality once programmed correctly. They can work continuously without breaks. Moreover, robots free up workers from being fixed to soldering tasks, allowing them to focus on supplying workpieces or other flexible roles.

Currently, we operate two production lines with two or three robots each, using five robots in total. Japan Unix representatives visit regularly to provide production advice, which is a great help.

Manufacturers now visit us to see the robots in action, often curious about how we maintain quality and whether robots can handle production. These visits often lead to discussions about new projects.

ROI Should Be Evaluated Across Entire Processes, Not Single Steps

Robots are costly to implement. How do you view ROI?

It’s true that the return on investment (ROI) for soldering robots alone may show a deficit when viewed in isolation. However, when you consider the entire process—from wire cutting to stripping, soldering, assembly, and inspection—automating the previously manual soldering step allowed us to increase production capacity and adapt to changes without adding more personnel. From a holistic perspective, the investment has proven profitable.

Moreover, if a project ends and orders stop, the robots can be repurposed for other tasks by adjusting their settings. Investing in robots is like paying salaries upfront, in a sense. Unlike human workers, robots don’t incur ongoing costs when production halts. Viewing the situation this way reveals the advantages of robots more clearly.

Exploring Laser Soldering Robots for Unreachable Areas

What are your expectations for Japan Unix’s soldering robots?

The robots are excellent, and the support is very satisfying.

That said, I’d like to point out one thing: Most soldering robots, related products, and soldering technology are fundamentally designed for mounting electronic components on printed circuit boards. For those of us soldering wire harness connectors, including our company, we often rely on trial and error within our existing knowledge when encountering issues on-site. This is especially true for the precise soldering work we do. Even slight differences can result in poor adherence or defects like spikes. The tip of the soldering iron is too small to observe with the naked eye.

It would be incredibly helpful if Japan Unix could develop products or technology dedicated to wire harness soldering.

What are your plans for future equipment purchases or line upgrades?

Soldering has been automated with robot implementation, and pre-processing tasks like cutting and stripping have been automated with laser equipment. The next step is automating transport and workpiece supply to achieve complete automation, replacing the parts currently handled by human workers. Additionally, we are considering laser soldering for the soldering process. With lasers, we expect finer control, enabling precise soldering in areas challenging for manual work.

Gaining Trust with Well-Equipped Factories and Facilities

Do you have a message for companies considering automation and robot implementation?

Changing your perspective significantly is crucial.

For small to medium-sized businesses with limited funds, equipment investments often seem like they won’t pay off. However, what if you viewed equipment investments as a way to secure new business and expand opportunities? Staying ahead of the market and customer needs with proactive “offensive investments” in equipment is essential.

In countries like China, processing companies actively showcase their facilities to clients, proposing with confidence: “We have the production capacity and technology to handle your needs, so trust us with your business.” In Japan, however, the traditional approach persists, where clients inquire about the capabilities and availability of processing companies.

From a client’s perspective, it’s easier to trust and assign work to the former type of company. Work naturally flows to companies equipped with the technology and facilities to meet customer demands. Japanese companies, including ours, must prepare the necessary infrastructure and mindset to qualify for client selection and adapt to this new approach.

Related Products and Services

Reference Videos

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español