Desktop Soldering Robot

SOLDER MEISTER

The new generation desktop soldering robot for Industry 4.0 and IoT.

UNIX-DF Series have improved its network function and robotic motion.

Three types, according to PCB size. These are also applicable and optimized for laser soldering.

It can connect with network, which can visualize each soldering process and result.

The additional two axes facilitate penetration angles or rotate PCB, which make difficult soldering component possible from now on.

Compact type

- Working area: 200mm×210mm

- New and improved heater

- LAN (Ethernet), COM port

- X,Y axis: 600mm/sec

- Z axis: 250mm/sec

- Separated soldering controller

Middle type

- Working area: 300mm×275mm

- New and improved heater

- LAN (Ethernet), COM port

- X,Y axis: 900mm/sec

- Z axis: 400mm/sec

- Built-in soldering controller

Wide type

- Working area: 400mm×365mm

- Supports M-size PCBs

- New and improved heater

- LAN (Ethernet), COM port

- X,Y axis: 900mm/sec

- Z axis: 400mm/sec

- Built-in soldering controller

- New heater improves heating and soldering mechanism.

- Productivity is highly improved by increasing rigidity and process speed.

- Connect with network and visualize the soldering operation process in real time.

- Two additional axes enables complex PCB and components soldering easily.

- Fully correspondent to laser soldering system.

Laser soldering specification

*UNIX-DF203L and UNIX-DF403L are also available.

Achieve 1) Improved network functions for industry 4.0

OPTION

Connecting to factory network and making operation visible in real time.

- The relationship between factory network and DF series.

PLC, LAN and hubs are as provided by customers.

- Supporting data export and external process control via LAN or COM port.

- Special monitoring software can remotely monitor operation status.

- The real-time monitoring such as temp. graph, operation status, errors can prevent defective products.

- Robots are controllable with connecting to PLC and with control commands.

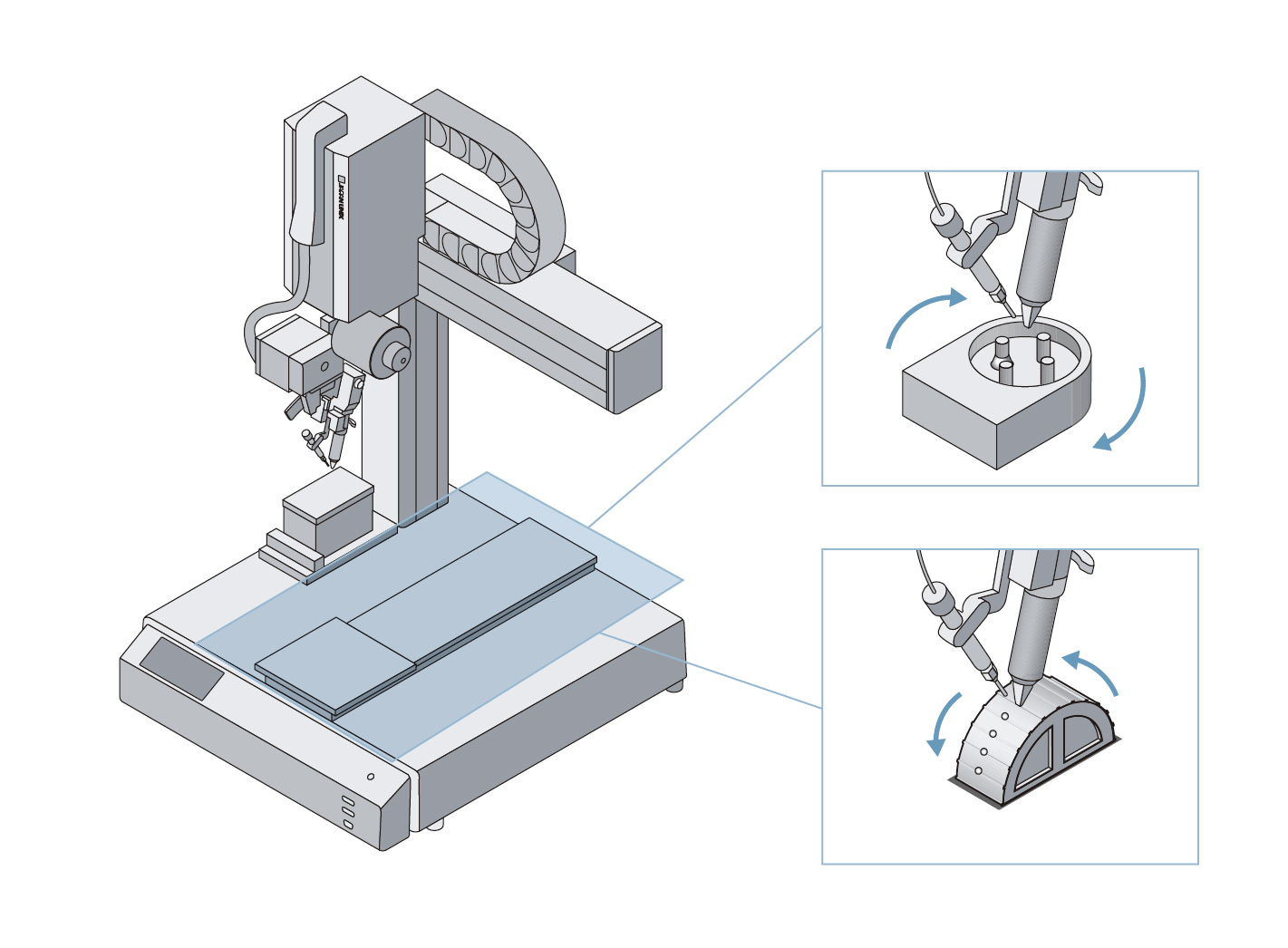

Achieve 2) 3D soldering and MID (molded interconnect device)

Two additional axes enable complex PCB soldering easy and flexible.

- Two axes can be added to the work area.

- Two axes can be optionally added, up to six axes are available.

- External devices are integrally controllable with the batch operation of robot.

- Various motions such as component rotation, PCB reversal, head angles, rotation of cylindrical parts, cable suppression, etc.

- Space saving and easy to setup.

Achieve 3) The new heater highly improves productivity.

Higher accuracy and improved temperature characteristics.

- Much more accurate temperature measurement has been achieved by placing heat sensor at the tip of the tip.

- Quick temp. recovery achieves higher operational efficiency.

- The heater and the tip are separated and can be replaced individually.

- Poka Yoke function prevents to make mistakes of installing a soldering tip and its direction.

Easy to change program selection on the switch box

- The center switch can quickly change programs.

- One touch selector on the switch box

- Arbitrary programs are simply selectable and executed (2ch)

Achieve 4) For Industry 4.0. Data management of each soldering process

By connecting DF monitoring software, various soldering processes such as temperature, program execution and so on are visualized and converted into numerical data.

For example, observing the temperature during soldering, if irregular temperature change or program execution occurred, the monitoring system captures their irregularity and can notify errors.

Furthermore, connecting to the Internet / intranet, the system can notify error and can send alert to the registered email. Such real-time observation enables you immediately respond to operation errors and defects.

Any data can be exported with CSV format. Various operational log data from each process can be useful for investigating and exploring for further productivity improvement.

Further advanced soldering management software “Soldering Manager” (paid version) is now available.

Reference Videos

Achieve 5) Managing invisible defect modes

UNI-TESTER compatible (optional)

In order to maintain stable soldering quality, not only measuring the tip temperature, but also measuring the tip leakage voltage and the ground resistance is important for process control.

The tip temperature instability affects the solder joint finish. Leakage and transient voltages can cause components’ internal damages. From the viewpoint of device protection, the resistance between the tip and ground must be measured and secured.

UNI-TESTER compatible with IEC-61191-1 (Ed3 / 2018) and IPC J-STD-001G can realize various measurements and automatic tip temperature offset at the same time.

Standard Configuration (Iron Tip Soldering)

Onboard controller

Controls robot and soldering operation.

High Precision solder feeder

Easy to change solder reel.

Patented

Clean-cut feeder

Reduces flux splatter and solder balls

Patented

Lock-on mechanism

Ensures steady feeding position and prevents slippage

Iron tip cleaner

Air blower type

Heater and temp. regulator for robotics

Special heater and temp. regulator with CA sensor

Patented

Soldering head

Easy to replace tips and heater within 1 minute.

Teaching pendant

Easy control and configuration

Option

Combining our rich array of add-on functions to make things faster, shorter, better quality and accuracy.

Tip Position Corrector

Automatically adjusts soldering position

Uni-tester

Soldering tester for both robotic and manual soldering

Brush cleaner

Remove carbide and dirt from the iron tip

High Precision Feeder

Supports ultra-fine soldering

Laser Unit

Non-contact soldering using laser

Consumables (soldering tips)

Select the suitable one from over 2,500 types

Selecting right soldering tip is the key for qualified outcomes.

The tip must be selected based on a variety of factors, such as circuit board material, components and their size.

Japan Unix has a wide range of high-performance iron tips developed for automation.

Manufacturer custom orders are also available for exclusive works.

*ATTENTION FOR COUNTERFEITS.

Counterfeit soldering tips are being found over the Internet and unauthorized dealers, etc., please be careful not to be deceived by such tactics.

More information

Three Methods to Choose From

Safe and reliable construction methods backed by tradition

Soldering with an iron tip has the longest history and is the most established technology in terms of reliability. However, modern technology requires a deeper understanding of soldering theory and new techniques to handle difficult applications

The latest soldering method that is attracting attention from around the world.

While laser soldering is gaining popularity as a new method, it cannot be used as a direct substitute for iron soldering, as the heating process varies. To fully benefit from laser soldering, it is vital to understand its characteristics and the appropriate handling techniques, otherwise its advantages may be lost. This article outlines the fundamental principles of laser soldering and the necessary precautions for its optimal use.

Ultrasonic turns conventional wisdom upside down. Soldering even on glass or ceramics

Conventional soldering basically involves bonding solder (tin) with a metallic substrate. Ultrasonic is an advanced technique that enables solder to bond with glass or non-metallic materials.

As renewable energy sources are attaining widespread use around the world.

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español