Desktop Soldering Robot

Product Range

Versatile Desktop Soldering Robot

Various model configurations and proven track record. Once programmed, all the operator has to do is press the start button. The same stable quality as that of high-skilled soldering operators is possible. The definitive soldering robot for a wide range of applications, from entry-level to high-reliability products.

UNIX-DF Series

Further evolution toward “Manufacturing IoT”.

The latest soldering robot with enhanced productivity, ease of use, and networking capabilities.

Three Methods to Choose From

Safe and reliable construction methods backed by tradition

Soldering with an iron tip has the longest history and is the most established technology in terms of reliability. However, modern technology requires a deeper understanding of soldering theory and new techniques to handle difficult applications

The latest soldering method that is attracting attention from around the world.

While laser soldering is gaining popularity as a new method, it cannot be used as a direct substitute for iron soldering, as the heating process varies. To fully benefit from laser soldering, it is vital to understand its characteristics and the appropriate handling techniques, otherwise its advantages may be lost. This article outlines the fundamental principles of laser soldering and the necessary precautions for its optimal use.

Ultrasonic turns conventional wisdom upside down. Soldering even on glass or ceramics

Conventional soldering basically involves bonding solder (tin) with a metallic substrate. Ultrasonic is an advanced technique that enables solder to bond with glass or non-metallic materials.

As renewable energy sources are attaining widespread use around the world.

Reference Videos

Robotic soldering

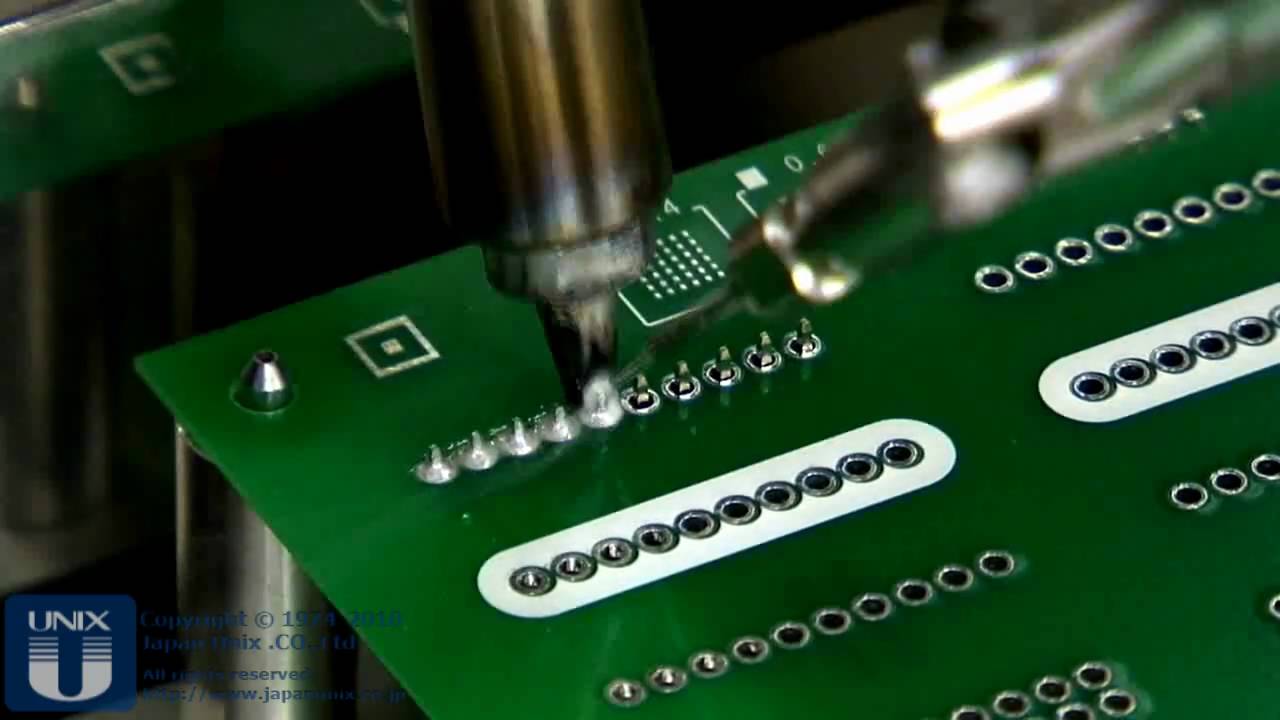

Automatic soldering robot: The High-speed Point Soldering

Point soldering is the basic soldering method. High speed and accurate soldering by dedicated robot.

Robotic soldering

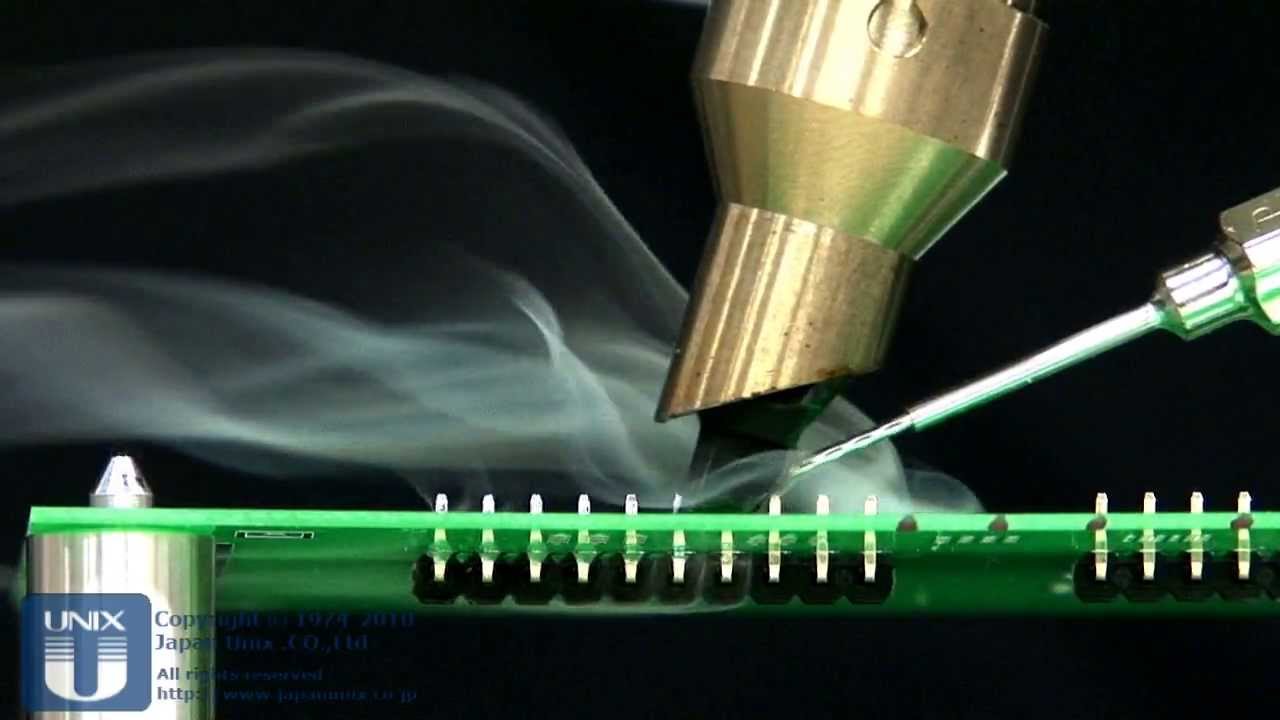

Continuous soldering technique for connectors: The Line Soldering

Soldering techniques called “drag soldering” and “continuous soldering” in production are called “line soldering”.

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español