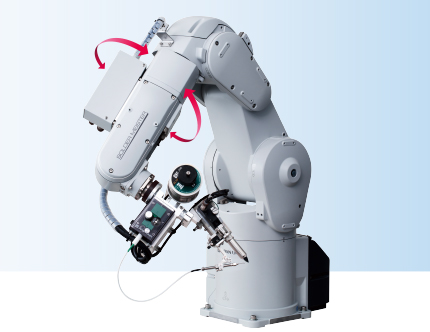

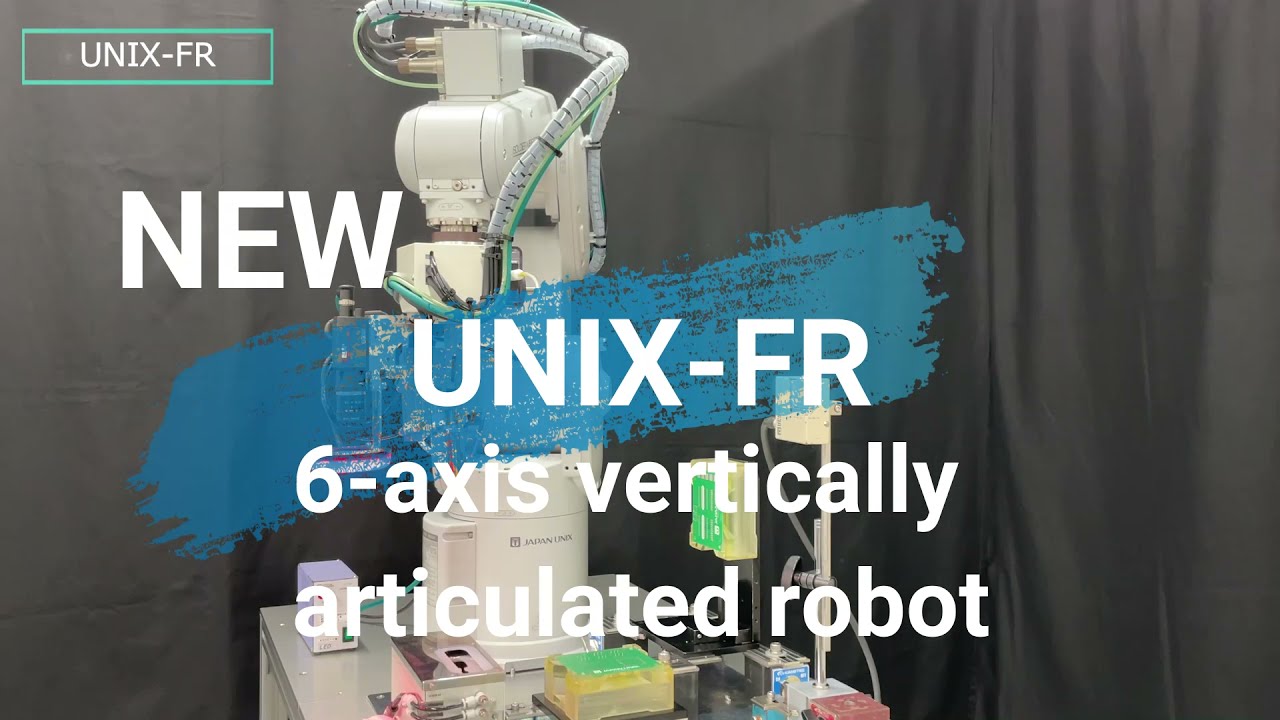

Vertical Multiple-joint Soldering Robot

New Generation of Vertical Multiple-Joint Soldering Robot

for the Era of Full Automation

Enhanced communication network function for output and storage of soldering-related data, and comprehensive software that can be used regardless of operator skill.

Of course, it is also compatible with SolderingManager for enhanced traceability. The new robot is designed to be more manpower-saving and easier to use.

Feature

3D Implementation Utilizing the Features of a Vertical Multiple-joint Robot

Utilizing the unique motion of a vertical multiple-joint robot, soldering can be performed not only on horizontal surfaces, but also on angled mounting surfaces from optimal angles. More flexible production is now possible.

Advantage in Installation Space

In addition to the mounting merits such as enabling 3D implementation, it is also effective in reducing the installation space. The size and movement of the robot itself requires less space than a horizontal multiple-joint robot. The optional tip 3-axis position adjustment mechanism can also be installed vertically, making the installation space more usable as a 3D space.

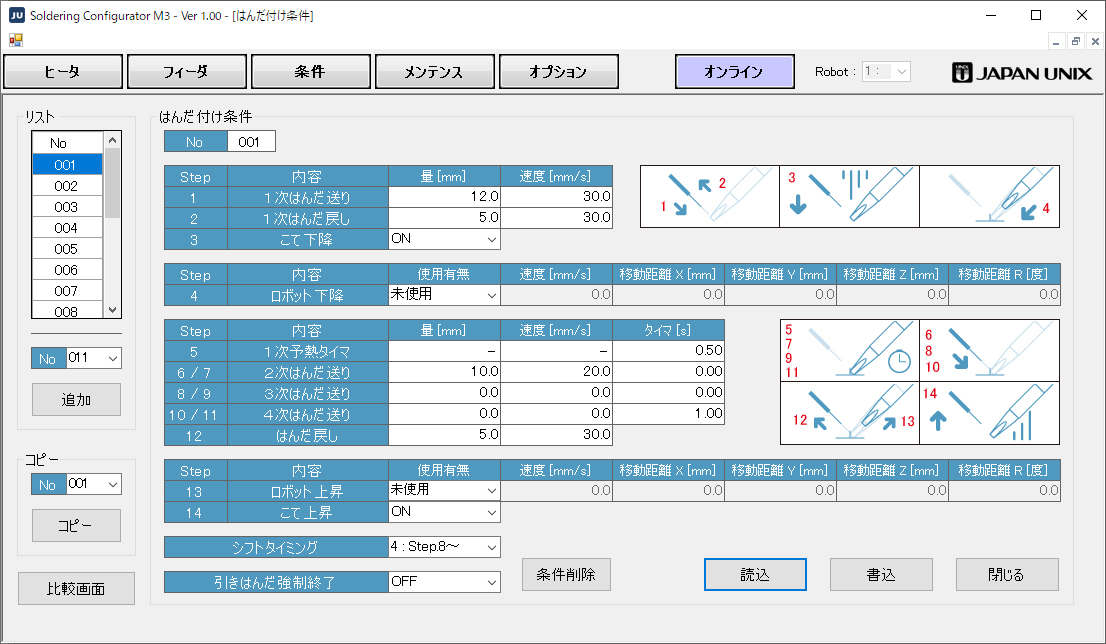

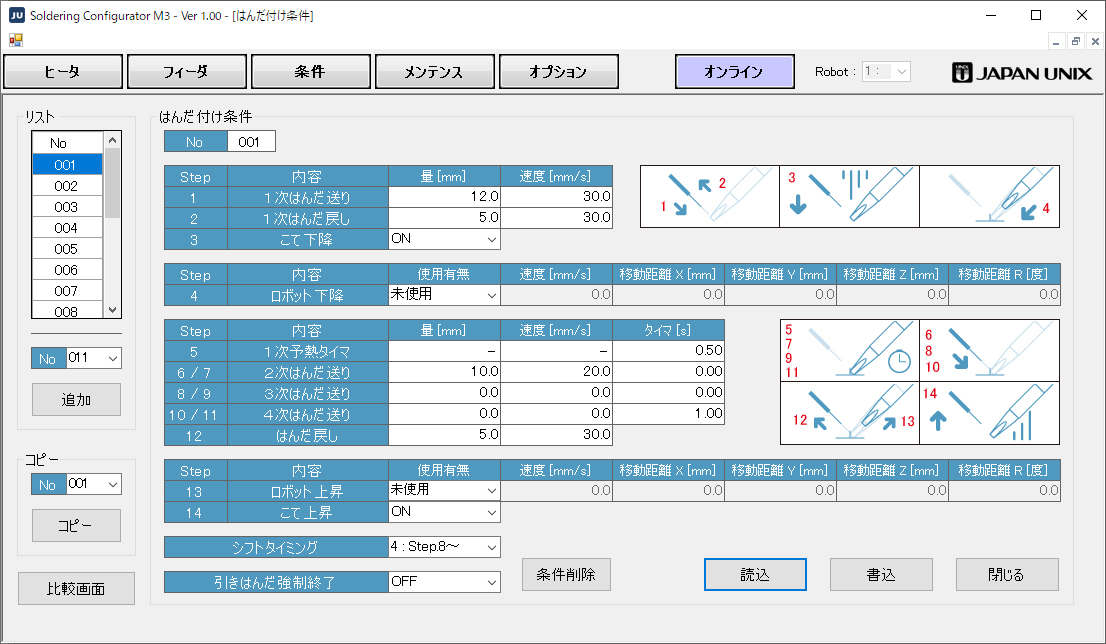

Soldering Condition Software

Soldering Configurator M3

Software for saving and editing soldering data. The software has an intuitive interface that allows step-by-step editing on a PC, enabling editing of soldering conditions regardless of operator skill.

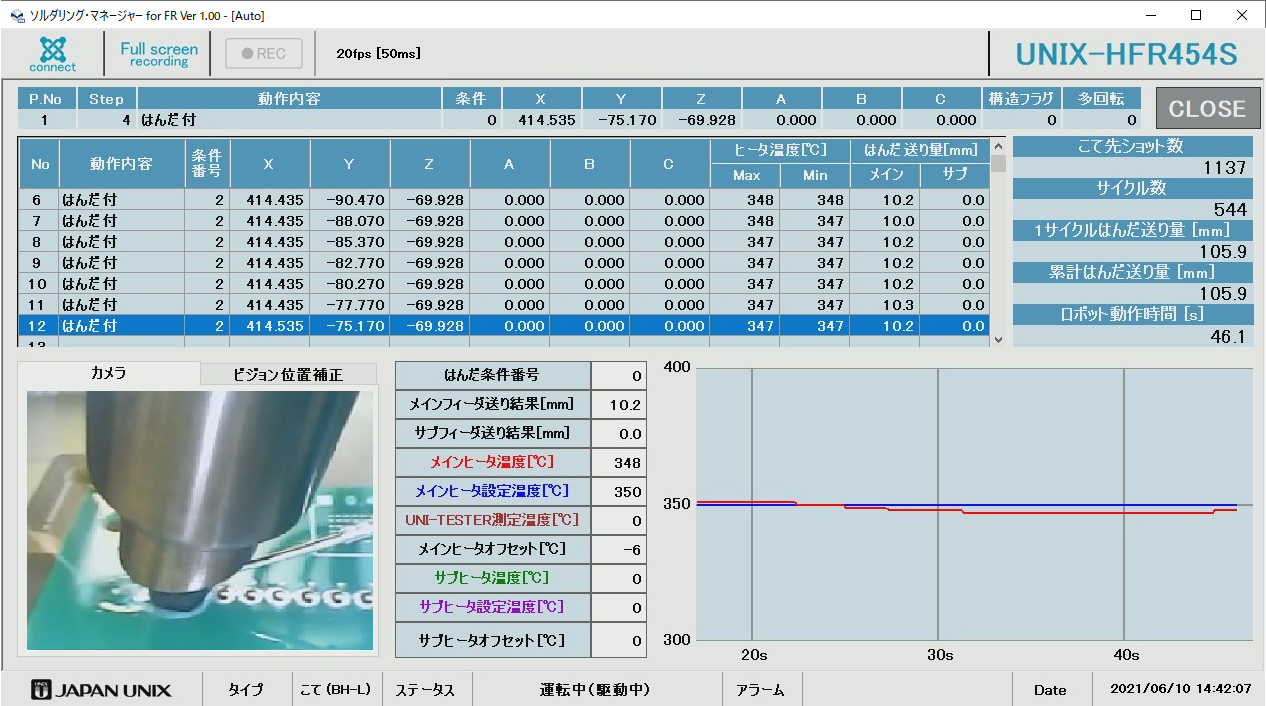

Monitoring Software

Soldering Manager for FR

Real-time monitoring and tracing of soldering robot operation status. Production status can be constantly monitored even in in-line production to reduce manpower. A camera mounted on the soldering head can also record video, and together with serial management by reading 2D code information, enhanced traceability is possible.

External Communication Function via Ethernet

Ethernet communication enables not only monitoring and tracing of operating conditions, but also external modification of solder condition settings. This makes it possible to edit conditions via a line-specific interface, enabling a more integrated automation line to be built.

Industrial Ethernet (Ethernet/IP) is also supported.

Standard Configuration

Iron Tips

Main Body of a Robot

Robot Controller

Soldering Controller

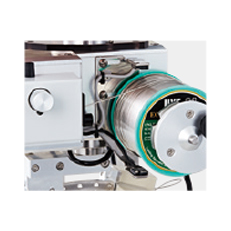

Standard Feeder

*Choose either one.

Clean Cut Feeder

*Choose either one.

Soldering Head/Heater

Lock-on Mechanism for Iron Tips

Cleaner Box

UJC-214

*Choose either one.

Cleaner Box

UJC-219

*Choose either one.

Soldering Condition Software

Soldering Configurator M3

Teaching Box

Option

Iron Tips

-Vision Sensors

Solder Remain-Level Sensor

Soldering Iron Tester

UNI-TESTER

Silicon Brush Cleaner

UJC-218

Three-axis Position Adjustment Mechanism

Soldering Manager for FR

Consumables (soldering tips)

Select the suitable one from over 2,500 types

Selecting right soldering tip is the key for qualified outcomes.

The tip must be selected based on a variety of factors, such as circuit board material, components and their size.

Japan Unix has a wide range of high-performance iron tips developed for automation.

Manufacturer custom orders are also available for exclusive works.

*ATTENTION FOR COUNTERFEITS.

Counterfeit soldering tips are being found over the Internet and unauthorized dealers, etc., please be careful not to be deceived by such tactics.

More information

Reference Videos

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español