Interview with Jabil Guangzhou : Road to Smart Manufacturing with Robotic Soldering

Case Study Interview: Jabil Guangzhou – Road to Smart Manufacturing with Robotic Soldering

As one of the world’s leading electronic manufacturing services (EMS) providers, Jabil operates over 100 factories globally, with Jabil Guangzhou being one of its largest and most critical manufacturing centers. Established in the 2000s, the factory produces a wide range of products, including automotive electronics, consumer electronics, and industrial and energy-related electronic components, with a particular emphasis on automotive electronics. To meet customer demands for high quality and stability, Jabil Guangzhou continuously upgrades its production equipment and actively integrates advanced automation technologies. In this transformation, Japan Unix’s desktop soldering robots have become an essential part of the factory’s automation strategy, significantly enhancing production quality and efficiency.

Desktop Robot UXIX-DF404S

Currently, Jabil Guangzhou operates over 50 desktop robots from Japan Unix, demonstrating its ongoing commitment to high-quality manufacturing. We had the opportunity to interview Jabil Guangzhou’s equipment manager to explore the factory’s operational model, how it maintains consistent quality across multiple product lines, and how it adopts the latest industry technologies to tackle future challenges.

Table of Contents

- Establishing a World-Class Manufacturing Center: Jabil Guangzhou’s Positioning

- Challenges Before Automation Adoption

- Choosing and Implementing Japan Unix Desktop Soldering Robots

- Enhancing Productivity Through Automation: Improvements in Quality, Stability, and Management

- Advice for the Industry: How to Successfully Introduce Automation

- Conclusion

- Reference Contents

Establishing a World-Class Manufacturing Center: Jabil Guangzhou’s Positioning

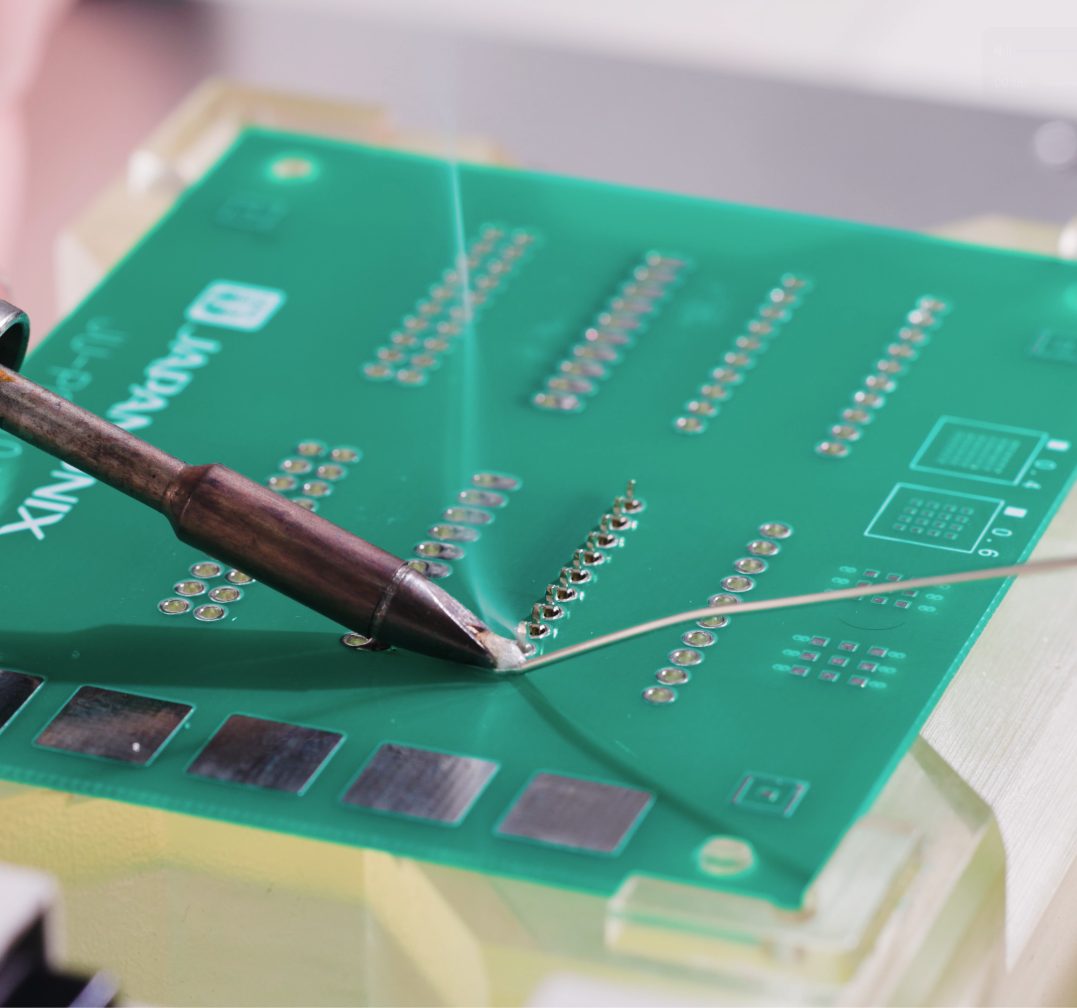

PCB Manufacturing Line Image

Since its establishment in the 2000s, Jabil Guangzhou has remained dedicated to becoming the most trusted manufacturing solutions provider for EMS clients. The factory’s core competitiveness lies not only in its advanced equipment and technology but also in its unwavering commitment to quality. Particularly in the field of automotive electronics, where product performance directly impacts human safety, Jabil must ensure that all components meet the most stringent industry standards.

The equipment manager emphasized that Jabil Guangzhou’s goal is to leverage the world’s most advanced equipment and the most suitable manufacturing processes to deliver the best possible products to clients. Quality always takes precedence—quality assurance ensures business survival, while cost control guarantees market competitiveness.

Challenges Before Automation Adoption

Before introducing automation, Jabil Guangzhou faced several key challenges. First, manual soldering had limitations in operational precision and consistency, making it difficult to maintain stable product quality. Additionally, as the variety of products continued to expand, traditional manufacturing methods struggled to keep up with increasing market demands. Rising labor costs also compelled the company to seek new strategies for optimizing its cost structure. The equipment manager pointed out that automation was the best solution to address these challenges, as it ensures product consistency and effectively reduces long-term labor costs.

Choosing and Implementing Japan Unix Desktop Soldering Robots

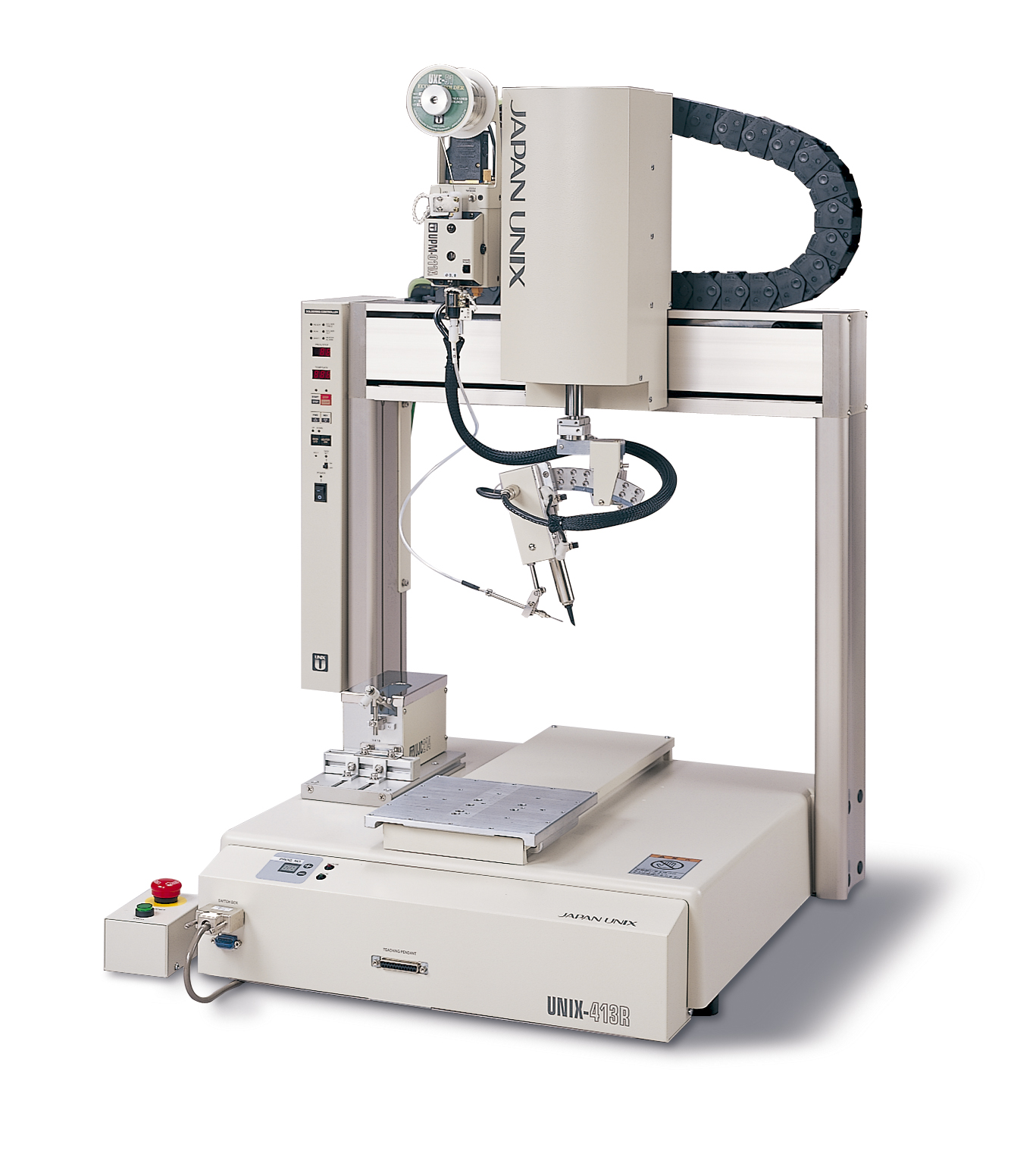

Old Model Desktop Robot

During the selection process for automated soldering solutions, Jabil Guangzhou conducted an in-depth evaluation and ultimately chose Japan Unix’s desktop soldering robots. These robots were selected due to their ability to support flexible soldering mode switching, making them adaptable to different production needs. Furthermore, they excel in soldering precision and consistency, ensuring that solder filling rates remain stable between 75% and 100%. Their compatibility with various product sizes also allows Jabil Guangzhou to meet the demands of a diverse and complex production environment.

When Japan Unix equipment was first introduced, some concerns arose within the factory, mainly regarding machine stability and return on investment. However, practical application proved that these soldering robots significantly outperformed manual soldering in terms of precision, stability, and operational flexibility, ultimately gaining widespread approval from the team.

Enhancing Productivity Through Automation: Improvements in Quality, Stability, and Management

Jabil Guangzhou’s journey toward smart manufacturing is still progressing. The factory’s future development of soldering robot technology will focus on two key areas. First, in terms of hardware, they plan to further enhance the level of automation, enabling robots to handle even more complex soldering tasks independently. Second, on the software side, Jabil aims to adopt the concept of a digital factory, promoting equipment connectivity and data collection while leveraging big data analytics to optimize production workflows.

The equipment manager emphasized that future factories will inevitably be data-driven. They hope to implement more advanced networking and data capture solutions to better monitor machine performance and achieve predictive maintenance.

Advice for the Industry: How to Successfully Introduce Automation

Based on Jabil Guangzhou’s extensive experience with automation, the equipment manager advises companies to conduct a comprehensive self-assessment before introducing automation equipment to clearly define their production needs. If a company’s primary goal is to reduce labor costs and improve product consistency, it should calculate the return on investment to ensure the economic feasibility of the automation plan. For large-scale production enterprises, highly automated equipment should be chosen, provided that the product has stable long-term market demand. On the other hand, companies involved in multi-variety, small-batch production should prioritize equipment flexibility to avoid excessive investment leading to prolonged machine downtime.

Furthermore, while automation reduces direct labor dependence, companies still need to cultivate highly skilled technical talent to manage and optimize automated equipment effectively. The equipment manager noted that although many believe machines will eventually replace human labor, in reality, high-end automation equipment still requires specialized personnel for operation and maintenance. Therefore, training employees with automation management capabilities is key to a company’s future development.

Conclusion

Through continuous advancement in automation, Jabil Guangzhou has successfully enhanced its quality, efficiency, and cost competitiveness, with Japan Unix’s desktop soldering robots playing a vital role in this transformation. As the era of smart manufacturing accelerates, Jabil is rapidly advancing toward digitalization and full automation, providing global clients with more reliable and efficient manufacturing solutions.

Related Products and Services

Click here for information on automatic soldering robots

Reference Video

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español