Soldering Controller USC-06

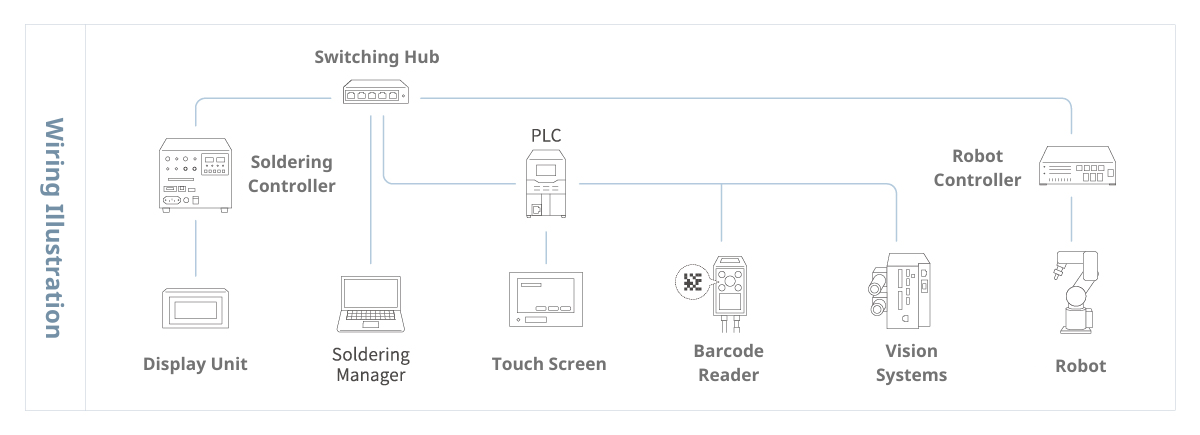

Data Communication with External Devices via Ethernet Connection

Unlocking Greater Expandability

A next-generation soldering unit enabling visibility into soldering processes through data communication and connection to various robots and equipment.

Features

Soldering Process Visualization

A next-generation soldering unit enabling real-time visualization of soldering processes through data communication and connections to various robots and equipment. Access critical data to enhance quality control, optimize processes, and support traceability.

- Accurate detection of solder clogging or wire breaks using an encoder

- Choice of heater types (AH/BH/AD) and soldering tip shapes to fit specific applications

- Dual independent connections to the soldering head and wire feeder, allowing simultaneous control of up to two soldering points

- USB connectivity for reading configuration data and acquiring log data

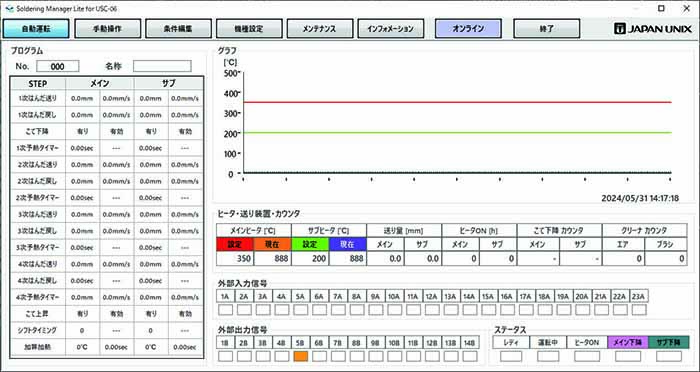

Standard Installation of Soldering Manager

- Real-time display of operational status via graphs and numerical data for visualization

- Edit, save, and manage soldering parameters

- Enhanced traceability measures

- Multilingual interface support (3 languages: Japanese, English, Chinese) ※Under development

Connection Overview

Diverse Options

Display Unit

Laser Soldering Unit

Laser Feeder

Feeder

Consumables (Soldering Tips)

Select from over 2,500 tip variations to find the perfect fit for your application. Choosing the correct tip is essential for ensuring high-quality soldering. Consider factors such as component size, board material, and specific conditions when making your selection. Japan Unix offers a wide variety of high-performance tips developed specifically for automated soldering. Custom-designed tips are also available to meet unique work requirements.

※ Beware of Counterfeits

It has been confirmed that counterfeit soldering tips are being sold online and through unauthorized distributors. Please exercise caution.

Learn more

Reference Videos

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español