Understanding Key Defect Factors and Enhancing Quality Control - Steve Honda

Basics of Soldering Automation

from the Perspectives of Defect Causes and Quality Control

The Necessity of Soldering Automation

In recent years, soldering automation has rapidly advanced in the Japanese manufacturing industry. The driving forces behind this trend include labor shortages due to an aging population and changing work styles, as well as issues with technology transfer. Particularly in local factories, the retirement of skilled workers and the shortage of younger technicians have become serious issues, leading to a lack of personnel for soldering tasks.

Furthermore, with the increasing electrification of all products, the number of people who have never encountered soldering technology is on the rise, making it necessary to advance automation while simultaneously learning these technologies.

Soldering requires precision work, and the quality directly impacts the overall reliability of the product. By introducing automation, it is possible not only to ensure stable quality but also to improve productivity and reduce costs.

Main Causes of Soldering Defects

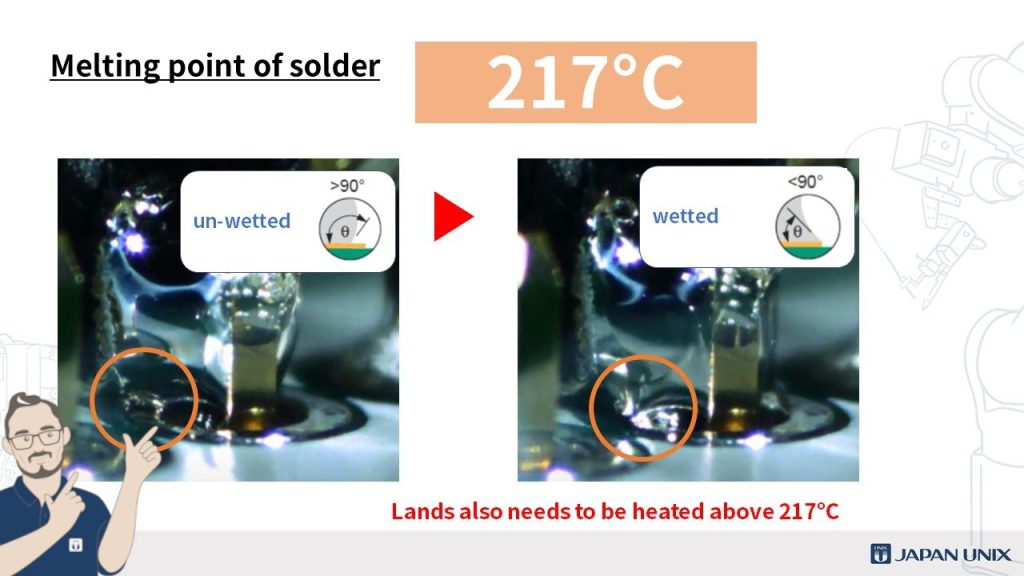

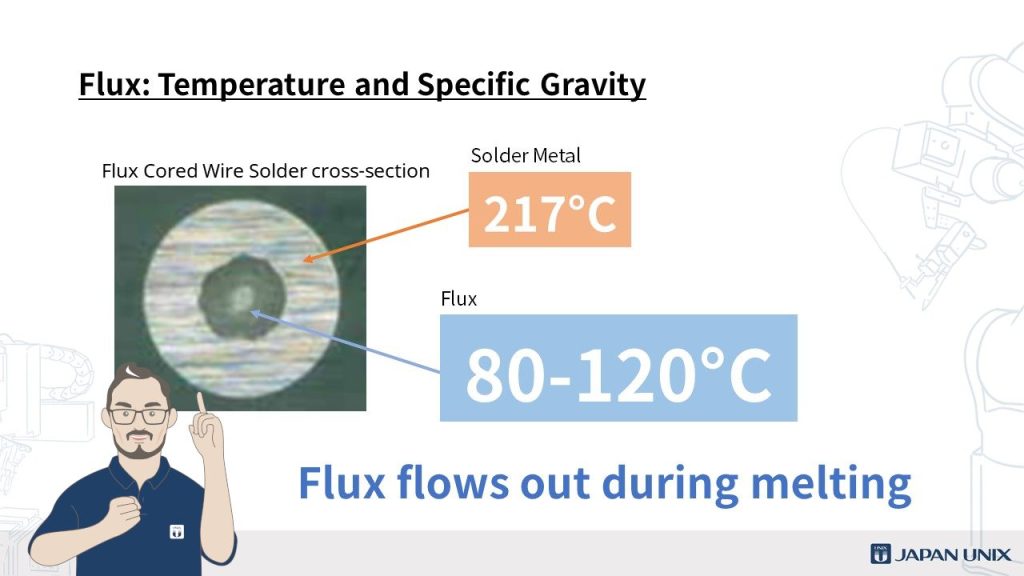

Soldering defects are often attributed to two main factors: “Heating” and “Flux.” First, regarding heating issues, “insufficient heating,” which fails to reach the melting point of the solder, is a common problem. The melting point of lead-free solder is typically 217°C, but if the base material does not reach this temperature, the solder will not wet sufficiently, resulting in poor bonding. On the other hand, excessive heating carries the risk of causing pattern peeling and reduced mechanical strength.

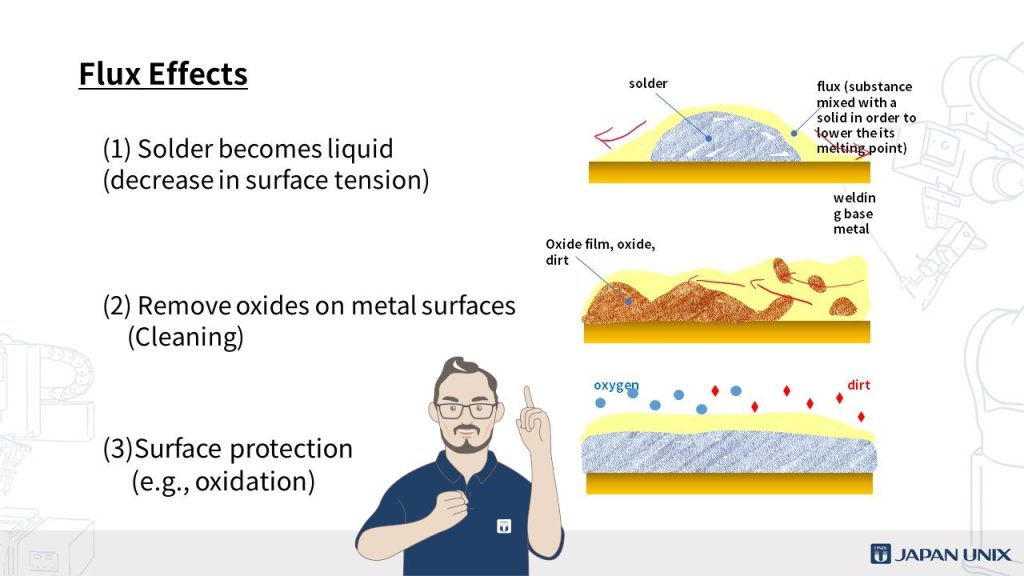

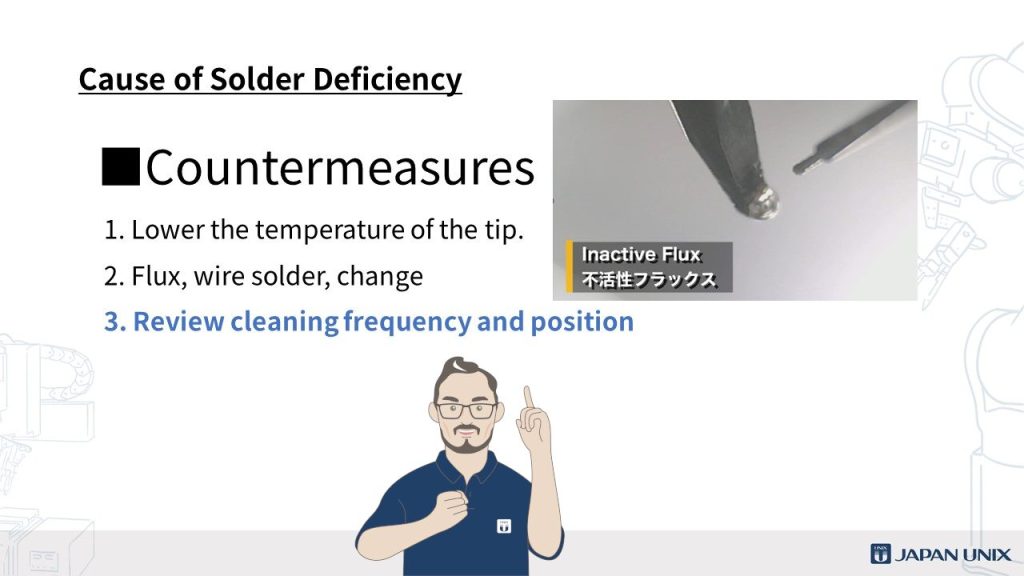

Next, flux plays a crucial role in removing oxides and reducing surface tension, but if it does not function properly, it can result in poor solder bonding and the occurrence of defects. When the flux becomes inactive or is insufficient in quantity, its effectiveness is compromised, leading to bonding defects.

Optimization and Measures for Heating and Flux in Automation

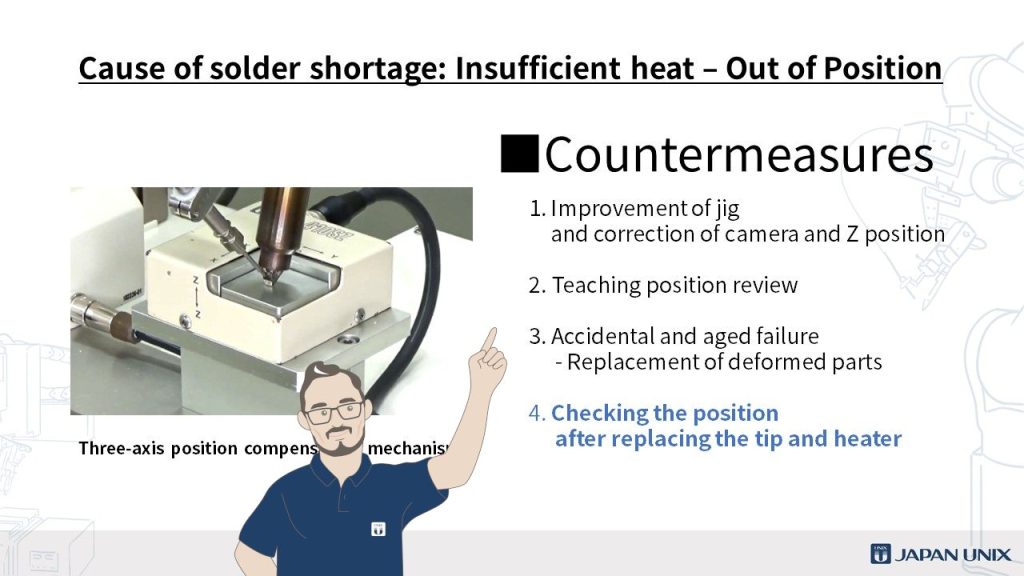

In an automated soldering process, it is necessary to consider the optimization and countermeasures for heating and flux. Regarding heating, selecting and managing the heating source, the shape of the soldering tip, its position, and its condition are required to appropriately control the temperature of the base material. For example, increasing the temperature of the soldering tip may temporarily improve bonding, but in the long term, it could lead to the deactivation of the flux and increase the risk of defects. Therefore, it is essential to properly set and manage the temperature.

For flux, it is important to pay attention to the characteristics of the flux components, their active state, and to supply them at the appropriate temperature and timing. By understanding the temperature at which the flux melts and the temperature at which the solder wets, and by aligning these, stable bonding can be achieved. Additionally, regular air cleaning is crucial to maintain the active state of the flux.

Quality Maintenance and Management

Amid a shortage of skilled labor, challenges in technical succession have also emerged in quality control. Naturally, quality management is indispensable in automated soldering. Moreover, maintenance is also a crucial element and a field issue in quality management. Daily inspections, scheduled periodic inspections, visualization of equipment status and results, as well as automation of maintenance and on-site education, are among the many actions that need to be taken care of. Japan Unix provides equipment capabilities and human support systems to meet the diverse challenges in the field, ensuring that customers can continue mass production with confidence.

Conclusion

The automation of soldering is an essential means to maintain factory production and improve productivity. However, its success requires a thorough understanding and optimization of basic factors such as heating and flux. Recognizing the importance of maintenance and management also enables the achievement of stable product quality.

As mentioned earlier, Japan Unix not only sells products but also provides technical and educational support. We offer online lectures using online meeting systems, where our Japan Unix technicians from on-site locations, technical bases in Japan, and domestic mother factories visit and conduct lectures with simultaneous interpretation. Please feel free to contact us for inquiries and consultations.

Related Products and Services

Here, you can find related products and services that support the quality and operational maintenance of your mass production sites.

Related Videos for This Article

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español