Steve’s Tech Article “Webinar : Soldering Robot - Strength and Weakness” [Must-See for beginners!]

Strengths and Weaknesses of Soldering Robots

Table of Contents

- Things Not to Do in Soldering

- Weaknesses of Soldering Robots

- Strengths of Soldering Robots

- Conclusion

Introduction

In this article, I will discuss the strengths and weaknesses of soldering robots. Understanding these factors is crucial for maintaining high quality soldering when using robots. Please consider these points carefully before deciding whether to install a soldering robot.

Furthermore, a weakness does not necessarily mean something is “impossible.” Instead, it indicates that the task requires creative solutions and ingenuity due to its high degree of difficulty. At Japan Unix, we have supported many challenging cases based on our 50 years of soldering experience, so please feel free to consult with us..

Things Not to Do in Soldering

First, let’s talk about things not to do in soldering. Avoid unrealistic cycle time shortening. In the past, pushing production under unrealistic conditions resulted in defects, and we had to revert to the original conditions. Merely adjusting soldering conditions has its limits, and proper flux application and preheating are necessary.

Also, avoid excessively increasing the tip temperature. Higher temperatures improve heat transfer to the board but also increase the occurrence of solder balls and flux splatter, and accelerate tip wear. Working at the appropriate temperature is crucial.

Moreover, neglecting maintenance is problematic. Deterioration of tips and equipment increases the risk of defects. Regular maintenance is essential to keep equipment in good condition.

Weaknesses & High-Difficulty Areas of Soldering Robots

Next, let’s discuss areas that are challenging for soldering robots.

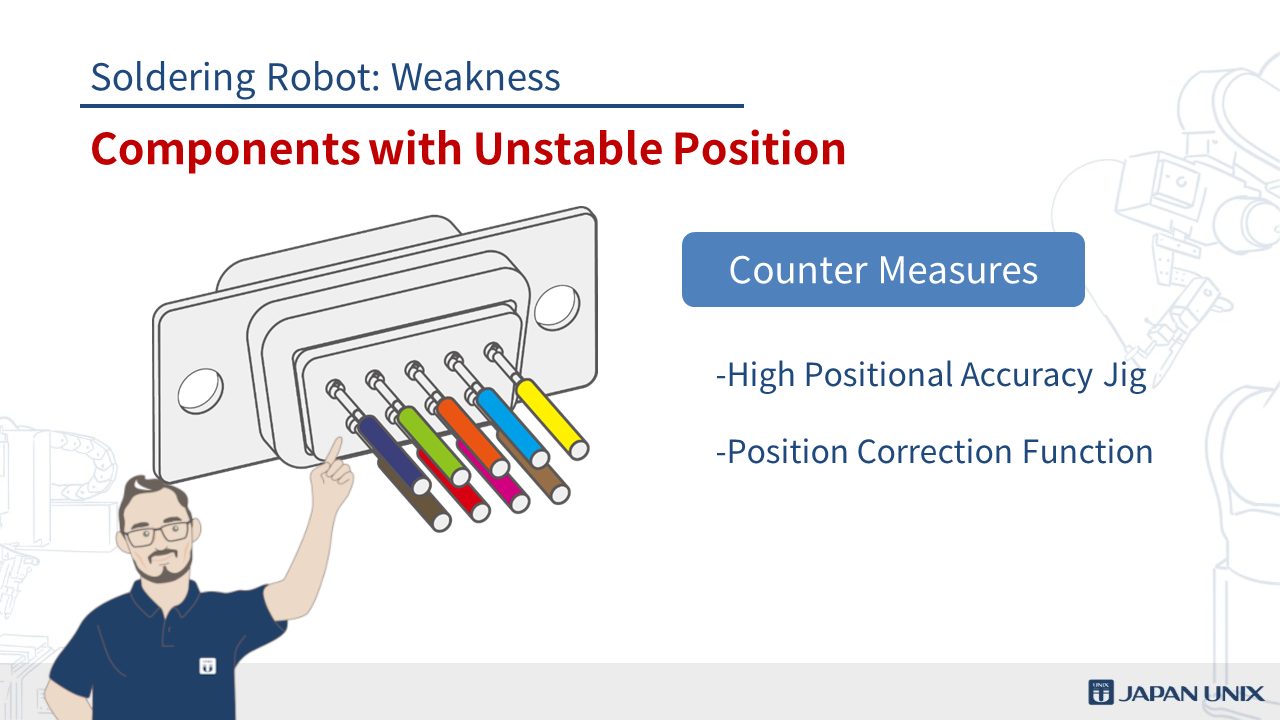

First, unstable positions are problematic. For items whose position varies significantly each time, it may be necessary to use jigs or robot functions for position fixation, or consider changing the acceptable quality range.

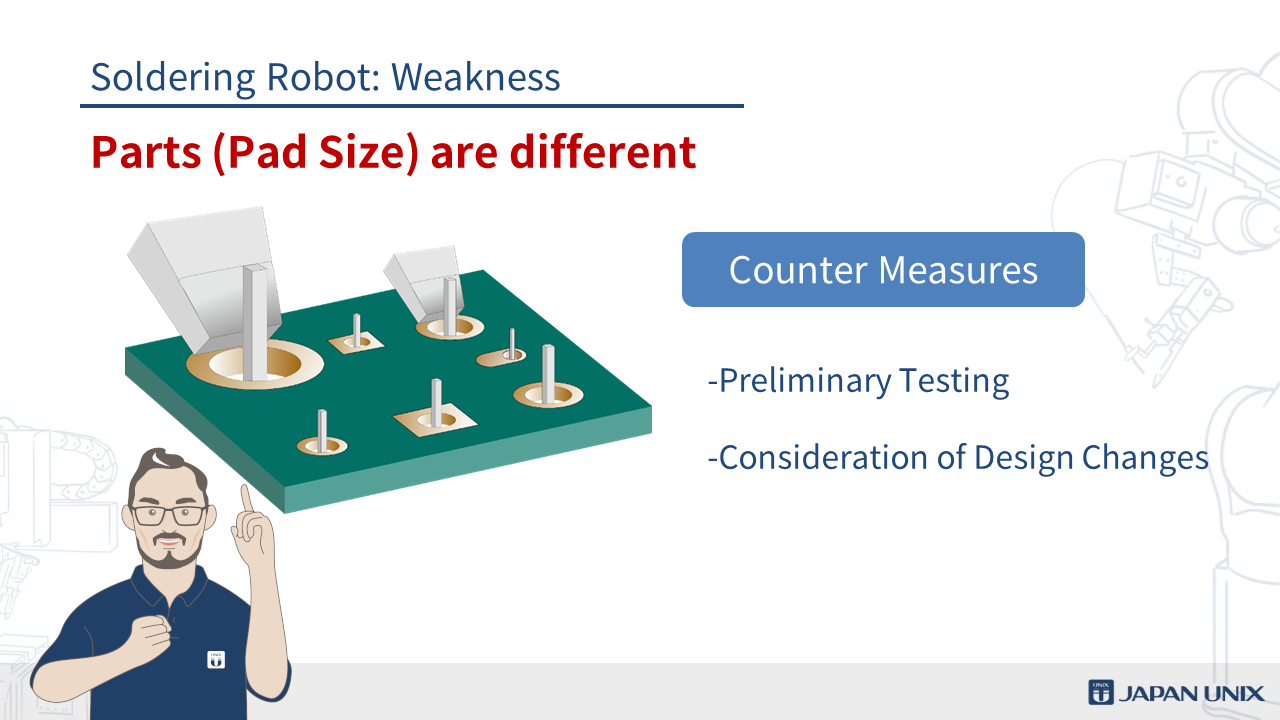

Additionally, varying sizes of components pose issues. Selecting the appropriate tip or laser spot diameter for different pad sizes is necessary. Improper size selection can cause defects, so consulting during the product design phase can lead to successful outcomes.

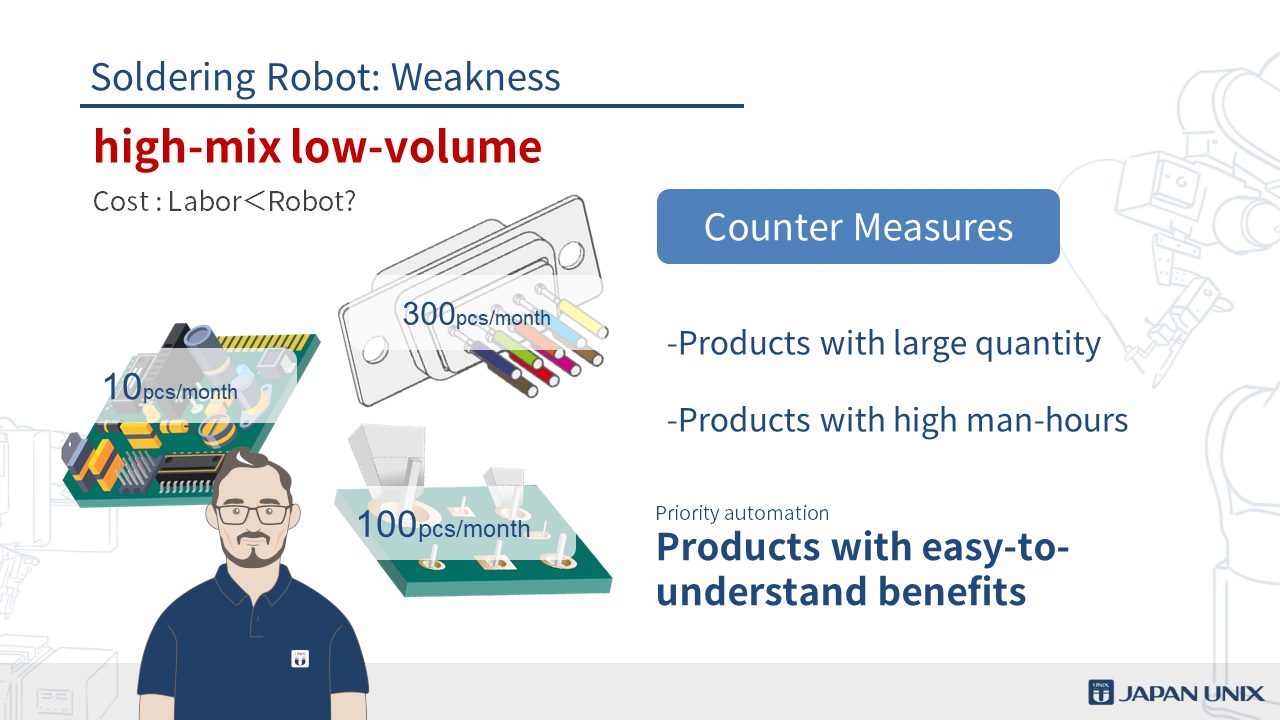

Lastly, soldering in high-mix, low-volume production is also challenging. Dedicated jigs are required, and managing these jigs and changing setups can be demanding. For high-mix, low-volume cases, it is difficult to realize investment benefits, so we recommend initially automating specific products where the benefits are more apparent.

Strengths of Soldering Robots

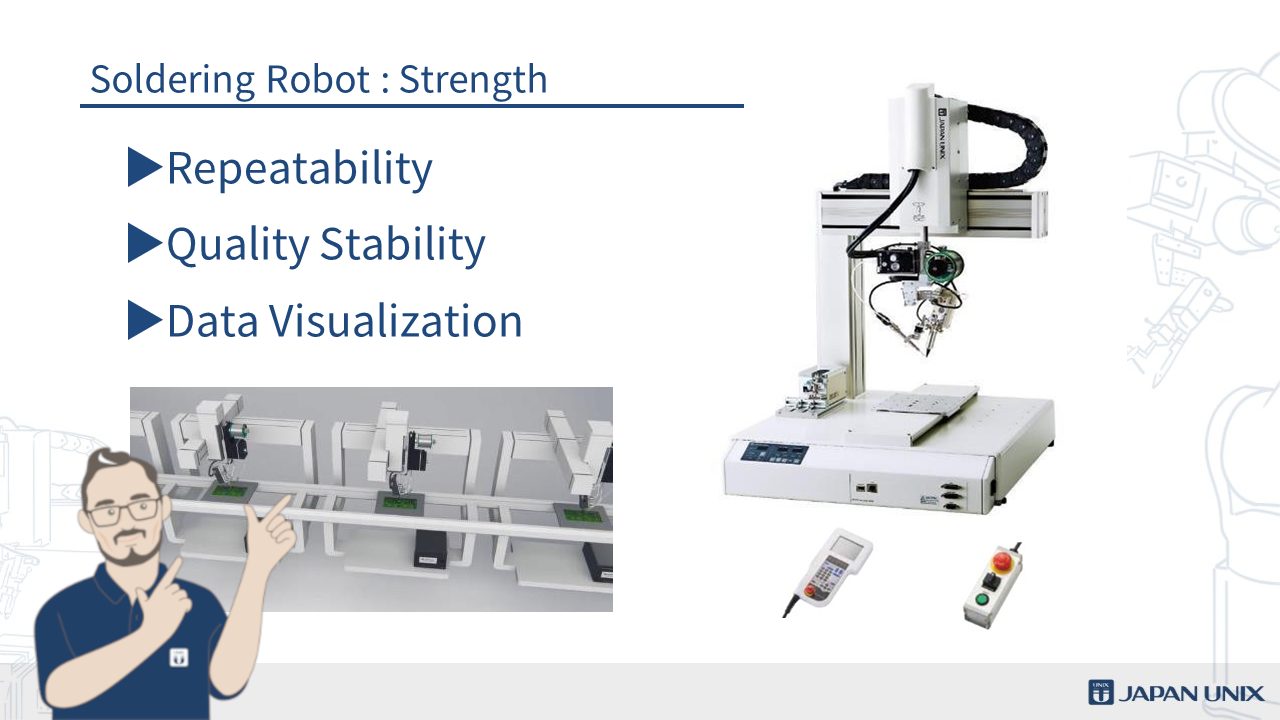

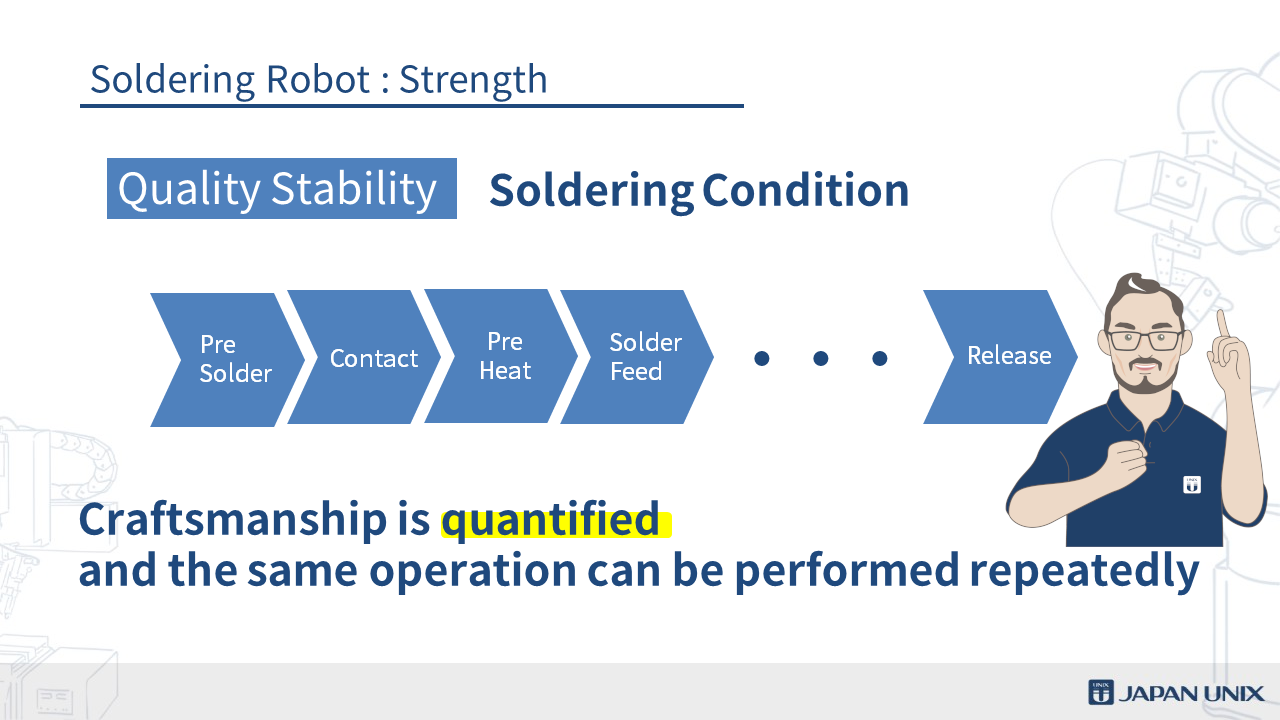

Next, let’s talk about the strengths of soldering robots. The biggest advantage of robots is repeatability. Robots work at set positions and times, providing high quality stability. Our soldering robots can maintain consistent quality by setting the soldering conditions.

Additionally, data visualization is possible. By using software called Soldering Manager to visualize data during operation, we can improve operations and enhance quality.

Furthermore, by using the robot’s position correction function, we can correct tip misalignment, achieving stable operations. By setting reference points and checking and correcting deviations from these points, we can prevent soldering defects.

Conclusion

Soldering robots have strengths and weaknesses. By leveraging the strengths and finding ways to address the weaknesses, effective automation is possible. For those considering automation, please consult with Japan Unix.

Related Products and Services

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español