[Nagoya]NEPCON JAPAN 2022 Exhibition Report

Nagoya Nepcon Exhibition Report. Introducing the Featured New Products!

Successful Conclusion of [Nagoya] Nepcon Japan 2022! At Japan Unix’s exhibition booth after a three-year absence, we introduced the latest laser devices as the main attraction, along with temperature control systems, in-line solutions, and technical support. Even if you couldn’t visit us, please take a look at Japan Unix’s total solution that supports “from soldering to mass production” on this page.

Overview of [Nagoya] Nepcon Japan 2022 Exhibition

Theme: “Visualization and Beyond”

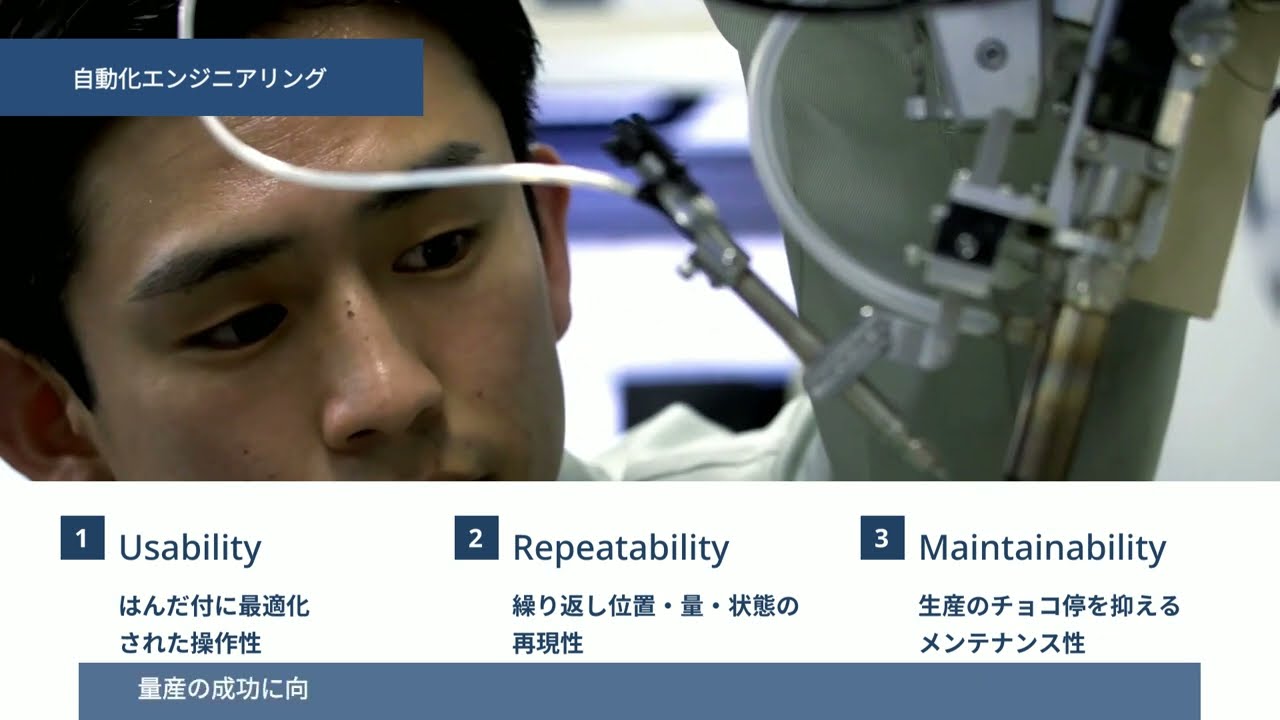

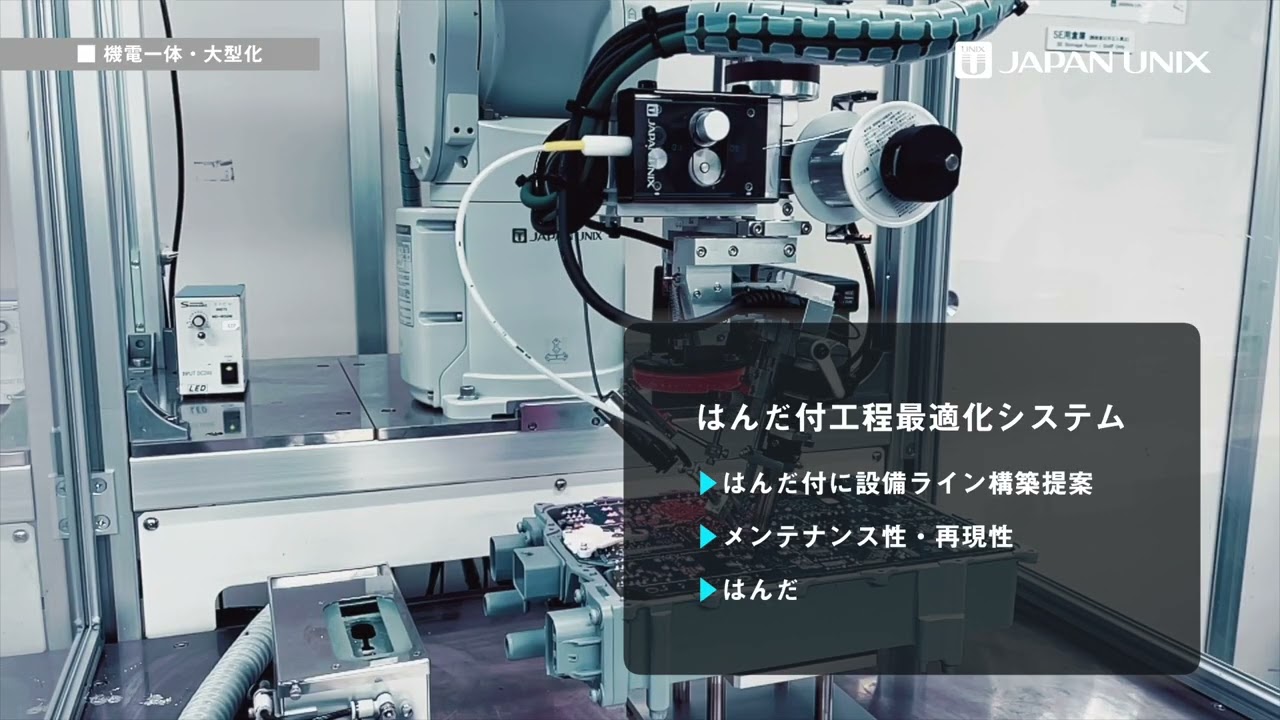

Japan Unix’s exhibition booth, held after a three-year absence, featured new devices and introduced various products and solutions. With the exhibition theme of “Visualization and Beyond” – Soldering Automation Equipment that Connects People, Things, and Society – Japan Unix proposes practical solutions that not only “visualize” but also contribute to the utilization of mass production sites.

Mass Production Process Control

By realizing thorough soldering process temperature control, traceability can be achieved, enabling visualization, graphing, recording, and video recording. The stored data can be easily shared and coordinated, leading to an increase in Kaizen speed.

Visualization of Power Consumption

Compared to overall heating, reducing local heating can reduce CO2 emissions. By using robots with lower heater power consumption compared to lasers and large-scale equipment that heat only when necessary, we contribute to achieving the recent goal of reducing CO2 emissions.

If you would like more information, you can download the PDF file from here. [Available until November 11th]

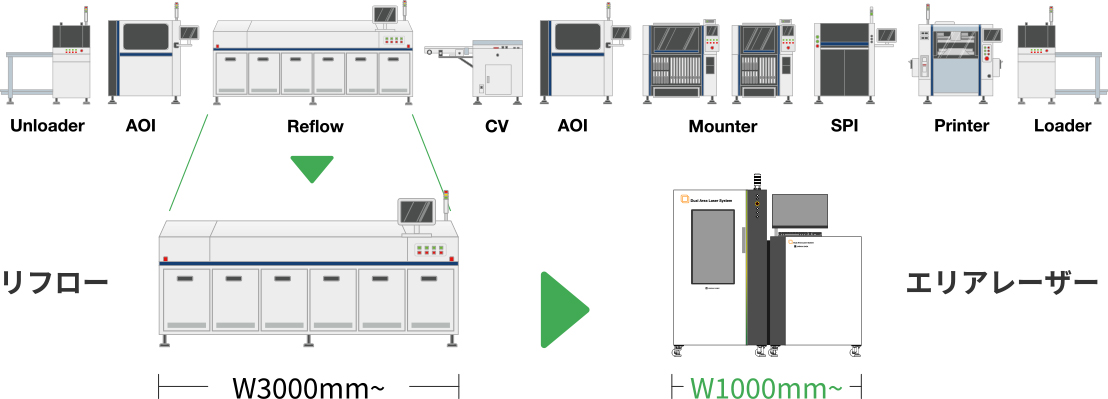

What are the New Area Laser Devices and Dual Area Laser Systems?

Double-sided Heating, Simultaneous Soldering at Multiple Points, High-output Laser

Compact, Space-Saving, Energy-Efficient

In the implementation line process that requires a large width, it can compactly utilize the space in the production site. Compared to other heating methods, it uses energy efficiently by heating only the required time at the localized area. It is strong in handling localized soldering of chip components, soldering of heat-sensitive parts such as connectors and cables, and precise soldering.

Application Examples

Area laser soldering is a new soldering method for high-density and compactly implemented components, connectors, cables, and other soldering applications in the modern era.

If you would like more information, you can download the PDF file from here. [Available until November 11th]

Reference Videos

Soldering on both sides and multiple sides simultaneously with dual area laser

Introduction of Japan Unix’s technical support system: Achieving stable non-stop mass production with post-installation support

Combining Laser Standard Mount and Thermo Pro™ for laser soldering process

and temperature control

日本語

日本語 中文

中文 Deutsch

Deutsch Español

Español